Avoid These 10 Violations to Prepare for 2025's Roadcheck

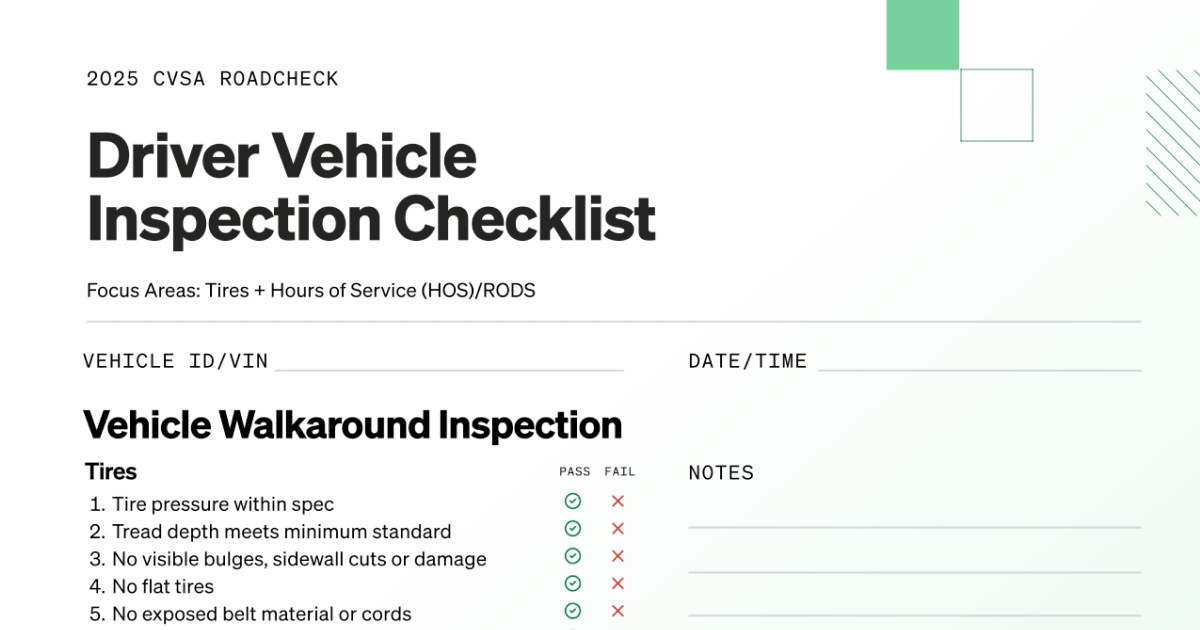

Every year, CVSA's International Roadcheck sidelines thousands of drivers and vehicles for non-compliance. This year, CVSA’s Roadcheck occurs between May 13-15 and will focus on tire safety and false driver logs. Learn from the top violations and grab a free inspection form to help your drivers and assets pass this year's Roadcheck with confidence.

Apr 23, 2025

14 min read

Content Overview

Get ready for CVSA Roadcheck 2025 with our free downloadable inspection checklist. This guide breaks down the top 2024 violations, key focus areas for inspectors in 2025, and practical ways fleets can boost compliance and safety before May 13–15.

Jump to a Section

What is CVSA’s International Roadcheck?

Every year, the Commercial Vehicle Safety Alliance (CVSA) puts trucking fleets to the test through an enforcement initiative called the "International Roadcheck." Over three days across the US, Canada and Mexico, CVSA-certified inspectors examine tens of thousands of commercial vehicles.

When they encounter a vehicle with a mechanical defect that violates CVSA’s North American Standard Out-of-Service Criteria, that vehicle is prohibited from operation for a specified time period or until the failed inspection item is remedied. By conducting these highly publicized mass inspection events, CVSA aims to remind fleets of the importance of following compliance regulations and make roads safer for commercial vehicle drivers across the continent.

What are the most common CVSA Roadcheck Infractions?

Recently, CVSA published the results of the 2024 International Roadcheck, providing the public with a breakdown of the most common reasons vehicles were taken off the road during the event. Let’s go over the most common compliance infractions affecting commercial vehicles as well as what fleets can do to prevent them.

| Driver Violations | Vehicle Violations |

|---|---|

| 1. Hours of Service | 1. Defective Brakes |

| 2. Missing Licenses | 2. Tires |

| 3. No Medical Card | 3. Other Brake Violations |

| 4. False Logs | 4. Lights |

| 5. Suspended License | 5. Cargo Securement |

How to prepare for CVSA Roadcheck 2025

The CVSA has announced that the 2025 International Roadcheck will be held from May 13-15. This year, inspectors will be paying close attention to two areas that have consistently ranked among the most-common issues each year: tires and false records of duty status (RODS).

With regards to tires, the CVSA has stated that inspectors will be looking out for signs of excessive wear, underinflation, damage, foreign objects and improper repairs. And when it comes to RODS, drivers should expect their submissions to be scrutinized for ELD tampering, “ghost drivers” (i.e. false claims of having a co-driver), and false reports of being off-duty while actually working. For a more in-depth explanation of this year’s focus areas, check out the CVSA’s official flyer.

Free 2025 CVSA Inspection Checklist

Tire Compliance: What Fleets Can Do

- Review tread depth and wear patterns weekly across all vehicle tires.

- Use digital inspections with photo capture to document tire condition.

- Train drivers to spot sidewall damage, underinflation and improper repairs.

- Log tire pressure checks and rotations in your fleet maintenance system.

- Leverage Fleetio’s Tire Management tool to monitor tire life cycles and replacement intervals.

As for all the other violations inspectors will be keeping their eyes peeled for, on the vehicle front, ensuring your vehicle’s components are securely in place and free of cracks or corrosion will go a long way towards keeping your vehicles in service. And if you have concerns about your drivers being sidelined, leading up to the Roadcheck, confirm that your drivers have all required records, certificates and licenses on them (and that all those documents are up-to-date) before they hit the road.

False Logs (RODS Violations): What Fleets Can Do

- Reinforce ELD compliance training—make sure drivers understand how to log correctly.

- Audit logbooks regularly to detect inconsistencies or ghost driver profiles.

- Educate drivers on the legal consequences of false reporting.

- Ensure ELD devices are tamper-proof and regularly inspected.

- Promote a safety-first culture that discourages overwork and cutting corners on logs.

Pro-tip

For more in-depth explanations of what inspectors will be looking out for, refer to the CVSA’s cheat sheets for vehicle inspections and driver inspections.

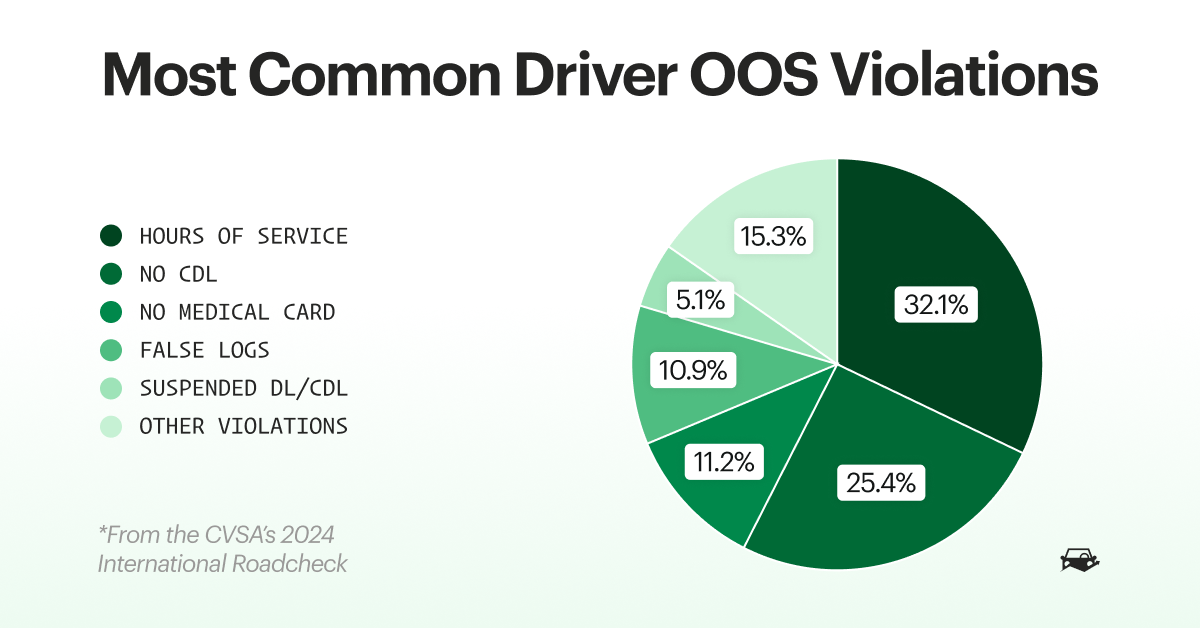

Top driver violations during CVSA Roadcheck 2024

1. Hours of Service

At a staggering 32.1% of all driver violations recorded, hours of service (HOS) infractions took 870 North American drivers off the road during this year’s International Roadcheck. For veterans of the trucking industry, the fact that HOS violations took the number one spot on this list likely doesn’t come as a surprise. Despite being required across all of the US for years at this point, many American carriers are still adjusting to ELDs. Industry surveys frequently find that a staggering percentage of carriers aren’t aware of or don’t fully understand the latest HOS rules. And due to parking frequently being difficult to find, drivers often end up exceeding HOS limits when trying to take federally mandated breaks. Partly for that reason, when the American Transportation Research Institute polled more than 4,000 motor carrier executives, drivers and other personnel on their top concerns this year, truck parking was the second most pressing issue.

But despite how pervasive HOS violations are in the trucking industry (and to fleets in general), organizations do have countermeasures available to them. First, the Federal Motor Carrier Safety Administration (FMCSA) has a wealth of online resources designed to demystify HOS regulations. From easy to understand explanations on driving limits, exceptions, reporting requirements and more, the FMCSA website contains answers to any HOS-related questions you’ve likely ever had. By keeping up-to-date on the latest developments, carriers can ensure they’re never in the dark on HOS policy updates.

As for challenges associated with ELDs and reporting, fleets should make sure that the training they provide to their drivers is actually equipping them with the knowledge they need on the road. While spending the time and investing the resources to reformat your training processes and reeducate your drivers does come at a cost, by reducing HOS-related fines, carriers will often end up with savings in the long run.

2. Missing/Suspended Licenses

Out of all the driver violations discovered during the 2024 International Roadcheck, 826 of them had to do with licenses (688 drivers had no licenses while 138 had suspended licenses). Despite being home to about 1 million commercial driver’s license (CDL) holders, in terms of infrastructure designed to alert companies that their personnel have had their licenses suspended, the US doesn’t have much. Only 17 states have Employer Notification Systems (ENS) in place; the rest rely on drivers self-reporting when their licenses are no longer valid. And while timely self-reporting is mandated by federal law, this lack of oversight is taken advantage of by unscrupulous vehicle operators. According to research conducted by the American Association of Motor Vehicle Administrators (AAMVA), somewhere between 50% to 80% of commercial drivers self-report, leaving a worrying percentage of drivers who disregard laws meant to keep our roads safe.

Fleets outside of the 17 states with ENS systems need to be more proactive if they want to confirm if their drivers’ CDL licenses are in good standing. The exact methods for obtaining driving records vary state by state, but they typically are fairly easy to obtain with driver consent. While it’s not practical to constantly request these files for an entire team of drivers on a regular basis, employers should make CDL validation a standardized part of their personnel management process if they aren’t already. Combined with a company culture that values honesty and compliance, fleets can take steps to curb rates of commercial driving with improper licenses.

3. No Medical Card

Federal law requires commercial drivers of vehicles that weight 10,000 or more pounds to obtain and maintain a valid Medical Examiner’s Certificate (colloquially referred to as a “medical card.”) But despite that requirement, inspectors at this year’s International Roadcheck found 304 drivers operating their vehicles without a medical card in their vehicle or on their person. The medical card requirement is designed to ensure that operators of commercial vehicles don’t possess any physical maladies that might pose a safety risk for themselves or others on the road. While different states follow different policies on how medical cards are obtained, renewed and enforced, being caught without a valid one is a major problem no matter what state a driver is in.

Fortunately, unlike the difficulties associated with suspended licenses, verifying that their employees' medical cards are in order is a very simple matter for fleets. Medical cards have clear expiration dates listed on them, so employers can instantly tell if one is still valid or not. To ensure their drivers don’t let these cards lapse, fleets can either ask drivers to present these cards to them on a periodic basis or they can maintain a database of when their drivers’ cards are set to expire (and remind them when they are in need of renewal).

Key documents — safe and secure

Never lose track of important fleet documents again. Fleetio’s secure cloud storage keeps everything — from licenses to insurance — safely at your fingertips, giving you and your team instant access to the files you need, whenever, wherever.

See how it works4. False Logs

CVSA-certified inspectors caught 297 American, Canadian and Mexican drivers with misreported logs this year. And unlike HOS infractions where there are a number of understandable (albeit not exculpatory) reasons for being in violation, false logs are much harder to justify. Even in a post-ELD mandate world, fraudulent reporting remains a pervasive issue for fleets of all sizes and industries. Despite the risk of receiving fines up to $2,500 per false log, drivers looking to subvert federal rules do everything from setting up “ghost” profiles to unplugging their ELD devices to operate beyond legal limits.

To curb the prevalence of false logs, fleets need to establish company cultures that value compliance and the safety and wellbeing of their drivers over maximizing efficiency at (nearly) any cost. By being mindful about overburdening drivers with excessive loads and simply staffing enough drivers to fulfill the hauls they require, organizations can go a long way towards minimizing the pressures that often compel drivers to flout the law. While it certainly won’t be easy to overcome the mentality behind “if the wheels ain’t turning, you ain’t earning,” endeavoring for a healthier balance between productivity and fleet safety is ultimately the best path forward for carriers and drivers alike.

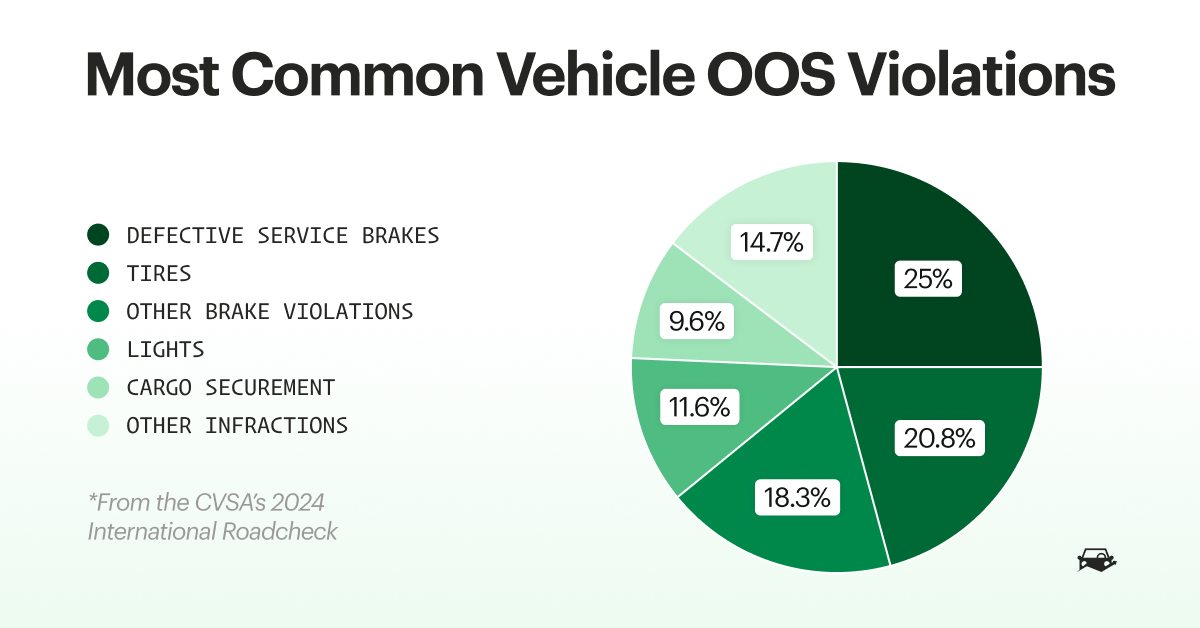

Top vehicle violations from CVSA Roadcheck 2024

1. Brake Violations

Noncompliant brake systems sidelined more than 5,800 commercial vehicles at this year’s International Roadcheck. According to the CVSA, they found 3,387 instances of defective service brakes and 2,486 instances of “other brake violations.”

And while you’re sure to find brake system examinations on virtually every pre- and post-trip inspection checklist, many fleets fail to scrutinize their brake systems to the appropriate degree. Since one flawed chamber, clamp, pushrod, slack adjuster, shoe or drum is all it takes to render a brake system unreliable, checking only a portion of a brake systems’ components is simply insufficient.

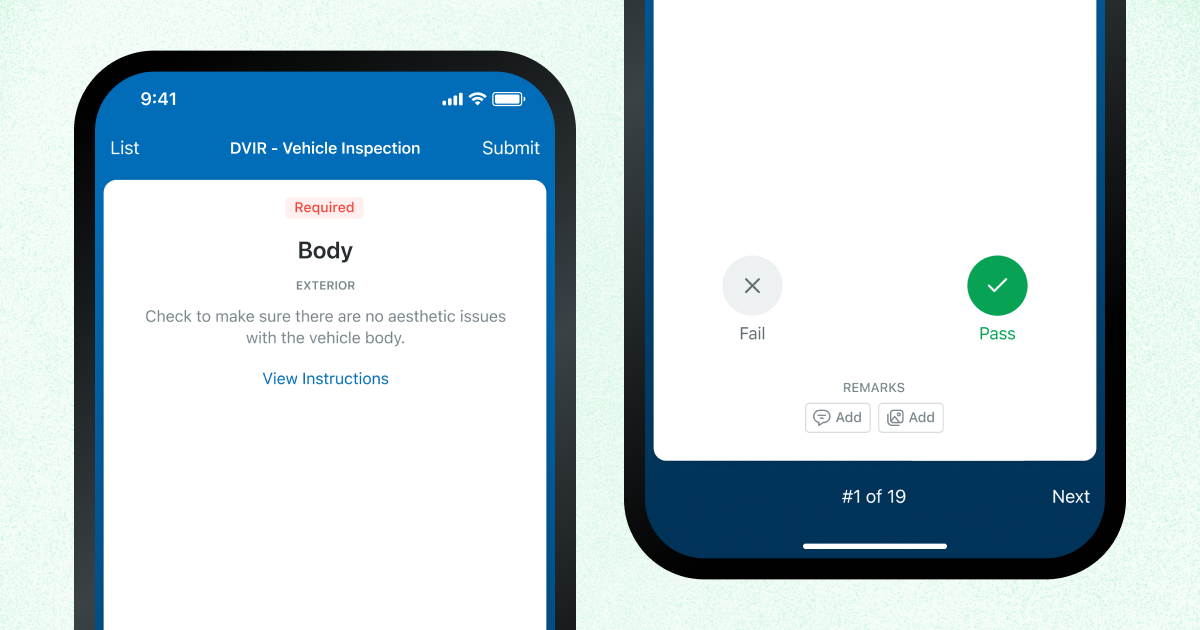

Instead, fleets should be comprehensive in their brake system inspections, examining certain components daily, others weekly, and remaining parts monthly (depending on their respective durability). Vehicle inspection apps can make staying on top of these different inspection tasks as simple as following the right checklist for the occasion. For example, these apps can direct users to be on the lookout for loose air chambers everyday, inspect rotors for cracks once a week, and check for air system moisture once a month. By ensuring no brake system component goes overlooked, vehicle inspection apps significantly reduce the likelihood of a vehicle being taken off the road due to the leading compliance infraction.

2. Tire Violations

While not as ubiquitous as flawed brake systems, worn-out tires were the reason more than 2,800 vehicles were halted at the 2024 International Roadcheck. From exposed fabric and belt material to insufficient tread depth, tires can violate CVSA-determined conventions in a litany of ways. And because tires are so vital to driver safety, a single tire having certain defects can instantly designate a vehicle to be out-of-service. Only roadside service calls can get vehicles back on the road once stopped as out-of-service — vehicles aren’t even allowed to go to the nearest truck stop to get their tires replaced or repaired. Because of this, fleets are both incentivized to take tire compliance seriously from both a safety and cost perspective.

Once again, as part of a larger fleet safety program, vehicle inspection apps can help address this all too common oversight. Using their smart device’s onboard camera, drivers can take pictures of any tire defects when conducting an inspection. This serves to create a record in the associated vehicle’s inspection history that can be reviewed at any time.

FOR FLEETIO USERS

Fleetio’s Tire Management feature allows organizations to closely monitor the health of their vehicles’ tires.

3. Lights Violations

According to the CVSA, more than 1,569 vehicles were placed out-of-service for having defective lights during this year’s International Roadcheck. Due to their nature, lights are among the easiest infractions to prevent and one of the most apparent flaws for inspectors to find. Whether being inspected by a driver or an enforcement official, a light can be determined to be in working order or not instantly through little effort. Because of this, a defective light is often the initial spark that leads to a more thorough inspection of the rest of a vehicle.

To identify malfunctioning vehicle lights as quickly and consistently as possible, fleets should instruct their drivers to look carefully when examining lights during the day. It’s not uncommon for drivers in a rush to mistake a light for being on when it isn’t actually operational (and is merely catching sunlight).

4. Improper Cargo Securement

According to the National Highway Traffic Safety Administration (NHTSA), unsecured loads result in about 730 fatalities and more than 17,000 injuries every year. To protect drivers and pedestrians from cargo-related mishaps, every state in the US has laws around unsecured loads and government agencies like the CVSA have detailed cargo securement rules. And at this year's International Roadcheck, inspectors found 1,303 instances of vehicles in violation of those cargo securement rules.

Inspections and driver training are the best tools fleets have to ensure their cargo securement practices are up to code. Before and after trips, have your drivers visually confirm that all tie-downs are in good condition. If any appear worn down or damaged, make sure they are replaced immediately. Chains, ropes, straps and similar items should also be inspected for signs of wear regularly.

That being said, the condition of your securement tools hardly matters if they aren't being used effectively. Thankfully, proper driver training can address this vulnerability. Educate your personnel on selecting the right tools for the job based on their working load limit (WLL). Teach them how to select securement points that will keep loads in place without causing any damage to your cargo. And train them on how to perform a thorough load check and how often they should be performing them.

Improve CVSA Roadcheck compliance with Fleetio

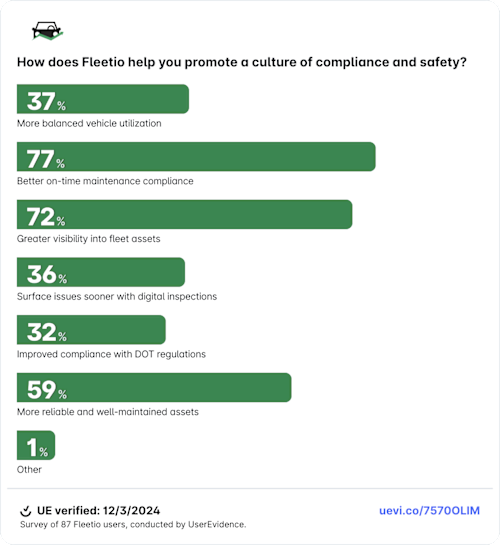

Ultimately, if fleets want to avoid having their vehicles sidelined during the next International Roadcheck, it behooves them to be diligent in their inspections and preventive maintenance work. Fleetio helps organizations excel in those areas by providing a comprehensive fleet management system that streamlines how information is shared among your personnel.

Compared to traditional paper inspection forms, Fleetio's digital inspections are more efficient to fill out and far easier to analyze. The ability to attach photos to inspections allows drivers to document defects with greater clarity. And if an urgent issue is discovered during an inspection, Fleetio immediately alerts designated administrators so they can create a work order ASAP.

Fleetio also helps organizations stay on top of their preventive maintenance more consistently by automatically tracking when scheduled maintenance actions are due. If a vehicle will soon need an oil change, Fleetio automatically issues a reminder so managers can assign that work to a technician. Fleetio even displays what vehicle manufacturers recommend in terms of when to perform different maintenance actions to help organizations optimize their schedules.

It's for these reasons and more why Fleetio users report that our software helps them achieve greater compliance and safety within their operations.

We have your back — and your fleet

See why thousands of businesses trust Fleetio to simplify their fleet management, giving them complete visibility and control over their vehicles, assets and expenses — all in one easy-to-use platform.

Let's walk you through

Fleet Content Specialist

Through interviews, blog posts and webinars, Alex covers the tactics and technologies exceptional fleet managers use to achieve results. By sharing their success stories, his work aims to inform and inspire fleet professionals of all stripes.

LinkedIn|View articles by Alex BorgReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304