Over more than thirty years in business, Des Moines-based commercial subcontractor Wolf Construction Services has undergone quite an evolution. What began as a way for Founder Scott Wolfswinkel and his friends to pay their college tuition has flourished into a multi-million dollar construction company. At first, the company focused exclusively on residential re-roofing, but, today, its portfolio of services also includes framing and trim carpentry (for homes and businesses).

And as Wolf Construction Services grew, so did the size and needs of its fleet. To stay on top of those needs, the company's fleet management approach has similarly evolved with the times.

So, to spotlight what compels organizations to choose the fleet management tools they use, let's explore Wolf Construction Services' journey from spreadsheets to Fleetio, past, present and future.

Spreadsheet struggles and paper problems

Back in the day, Wolf Construction Services kept track of their vehicles and equipment with the go-to tool of countless fleets—spreadsheets. That approach worked well enough for years, but, eventually, the company realized that Excel’s limitations were holding them back. So, to keep track of their assets more effectively, Wolf Construction Services implemented their first fleet management system (FMS).

Because it was specifically designed to meet the needs of fleets, the FMS was a major step up from spreadsheets in terms of ease of use and operational visibility. But, over time, the FMS’ own shortcomings started to come into focus. After a while, Fleet Manager Michael Smith felt the software was more suited for organizations with a handful of assets, not a fleet worth more than $100 million.

On top of that, the software was a desktop application, meaning it was only accessible from Michael’s computer. That restriction severely limited how beneficial the FMS could be to Wolf Construction Services’ fleet personnel as a whole. With no other option, technicians had to record their work with paper shop tickets.

Filling out those tickets was a time-consuming ordeal, especially for complex repair jobs that required lots of information gathering and writing. Too often, technicians found themselves holding pencils instead of wrenches.

Everyone hates writing for 30 minutes. [And], sometimes, some of those shop tickets would take 30 minutes to write out. Michael Smith, Fleet Manager

What’s more, because Michael had to spend hours each week manually entering those tickets into the FMS, his bandwidth as fleet manager was also impacted.

Knowing there had to be a better way, Wolf Construction Services began a search for a new FMS. And that’s when they discovered Fleetio.

Drop the spreadsheets — pick up the solution

More than just software, Fleetio is your fleet’s solution to missed maintenance, preventable breakdowns and costly downtime. It’s that simple — try it for free today!

Give it a test runGaining productivity with Fleetio

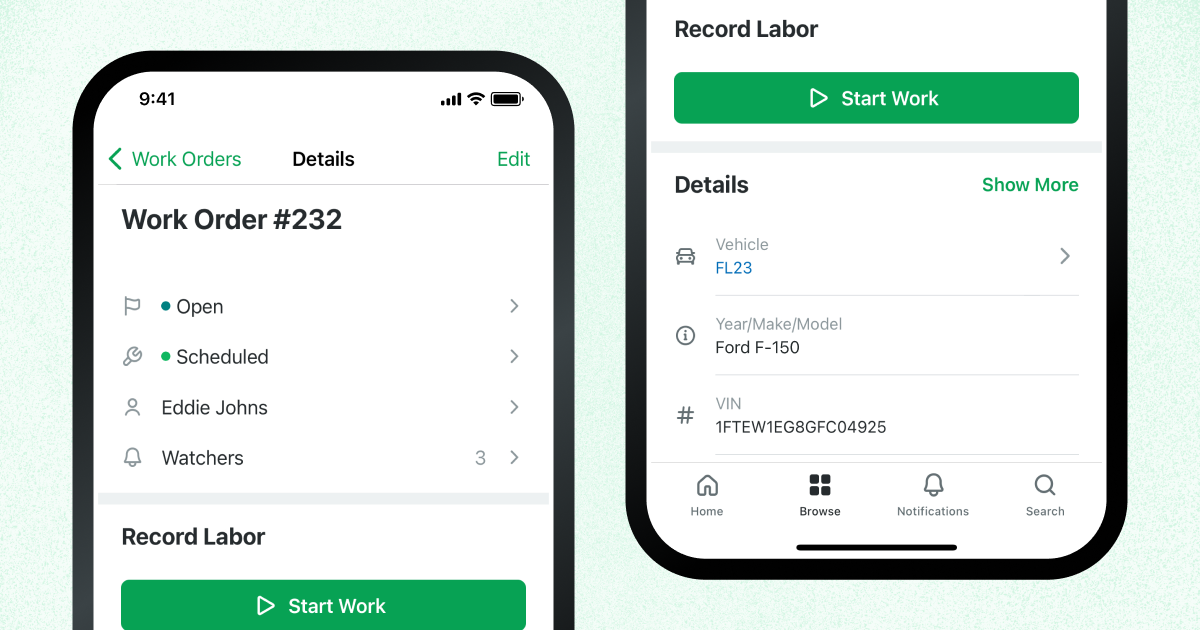

For more than two years, Wolf Construction Services has been using Fleetio to streamline their fleet operations. Now, paper shop tickets are a thing of the past as technicians log their work into Fleetio from their phones, saving them hours each week.

With Fleetio, mechanics don’t have to write out part numbers in full digit by digit. Instead, once a mechanic types in the first few numbers, Fleetio automatically displays a list of relevant parts that have been entered into the system. From there, the mechanic can simply select the part they want to add to their service task.

According to Michael, time-saving features like that have been a real gamechanger. Before, completing paper shop tickets was so time-consuming that technicians would often get interrupted as they were filling things out. By the time they'd return to writing, mechanics would often have forgotten critical details, resulting in them having to find information again (and making a slow process even slower).

But now, because data entry is so much more efficient with Fleetio, mechanics log their work so quickly that there isn't even time to get distracted on something else mid-way through a ticket. And less time filling out forms means more time for wrenching.

Plus, speaking of time, Michael no longer has to spend hours each week on data entry. As soon as a technician makes an update to a service task on their phone, it's automatically reflected in Fleetio. While he still reviews shop tickets to ensure data accuracy, double-checking takes a fraction of the time he used to spend transcribing shop tickets.

I don't have to sit there and type them in. I choose to review them just to make sure they're correct and nothing gets missed... That's saving hours a week not doing that. So [Fleetio] definitely increases efficiency and productivity. Michael Smith, Fleet Manager

Thanks to no longer being burdened by data entry, Michael has more time each day to focus on the long-term well-being of Wolf Construction Services' fleet.

Using Fleetio to plan for the future

One of the major benefits of using an FMS is, over time, fleets collect a wealth of historical data they can use to inform their future decision-making. And while spreadsheets accumulate data too, the reporting options FMSs provide to interrogate that data are tough to replicate.

Wolf Construction Services intends to leverage their data on how their assets' maintenance costs change over time to refine their vehicle replacement strategy. At present, the company generally replaces its vehicles after ten years or 200,000 miles and its construction equipment once they've seen eight years or 10,000 hours of use. And while those figures are partially based on past expenses (albeit a limited amount of data), Michael believes working with a larger dataset could help optimize their replacement schedule.

That's kind of an arbitrary number that we came up with from looking at financials back when we had a lot less data to go off of. But, now that we have Fleetio, we have the ability to capture more data and have our costs and everything in one place so we can make a better decision... Maybe we need to replace them at 150,000 rather than 200,000. Michael Smith, Fleet Manager

Regardless of whatever time, mileage or utilization metric Michael ultimately decides on, with dedicated personnel, proven processes and capable software at its disposal, it’s safe to say that Wolf Construction Services’ fleet is in good hands.

Optimize your fleet maintenance management

Wolf Construction Services streamlined its operations and gained unmatched visibility with Fleetio. Discover how your fleet can achieve the same success.

Book a Demo