Making decisions about fleet asset replacement doesn't have to be a guessing game. With the right data and fleet management strategy, you can develop a replacement approach that improves safety, reduces downtime and optimizes your total cost of ownership (TCO) across your fleet.

Why does your fleet need a vehicle replacement and lifecycle management plan?

Managing a fleet without a structured vehicle replacement strategy is like driving without a GPS – you might eventually reach your destination, but it creates a lot of opportunities for unnecessary detours and lost time (and money). A well-planned vehicle replacement strategy tells you when to cycle out aging assets while serving as your roadmap to maintaining a high-performing, cost-effective fleet.

What happens when fleets operate without a replacement strategy? Maintenance costs climb unpredictably. Downtime increases as aging assets require more frequent repairs. Fuel efficiency decreases. Driver satisfaction drops. And perhaps most importantly, you miss opportunities to maximize the resale value of your assets.

It’s a stark outlook, but there’s a really easy solution. Taking a strategic approach to asset replacement helps you:

- Reduce unexpected breakdowns by replacing assets before they become maintenance liabilities

- Optimize your maintenance budget by avoiding costly repairs on aging equipment

- Improve operator safety with regular updates to newer, safer models

- Maintain consistent budgeting through planned, predictable replacement cycles

- Maximize resale value by timing disposals before heavy depreciation

- Take advantage of new technology and fuel efficiency improvements

Aging assets? Rinse and replace.

Find out the right time to retire an aging vehicle and how to make the smartest replacement decisions with our ultimate guide.

Download your free guideUnderstanding total cost of ownership in vehicle replacement

When fleet managers fall into the trap of making decisions based on immediate needs rather than long-term lifecycle management, it often leads to increased TCO and missed opportunities for optimization.

A well-planned approach to asset retirement transforms your operations from reactive to proactive. You'll see the financial benefits quickly through reduced maintenance costs and optimized resale timing. Modern assets typically deliver better fuel efficiency too, which can significantly reduce your operating costs, especially across larger fleets.

Beyond the financial impact, strategic lifecycle management improves your fleet's reliability. You'll experience fewer unexpected breakdowns and less asset downtime. This reliability directly affects your service quality and team satisfaction. Plus, newer assets come equipped with advanced safety features and improved technology that help keep your operators safe and productive.

Key performance metrics in vehicle lifecycle management

Success in fleet asset management starts with tracking the right performance metrics. Let's explore the data points that should inform your replacement decisions.

Cost Per Mile: Your essential performance metric

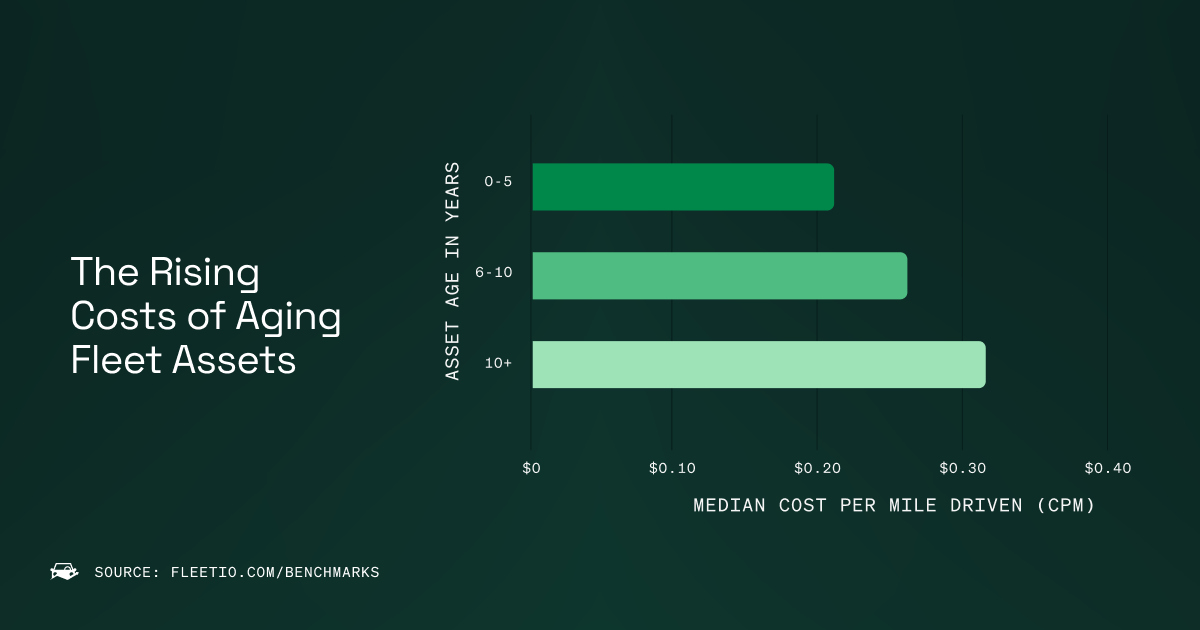

Cost per mile (CPM) provides a comprehensive view of asset performance and total cost of ownership. This calculation includes all your operating expenses, from fuel and preventive maintenance to depreciation and insurance. By monitoring CPM throughout an asset's lifecycle, you can identify when operating costs begin to outweigh the value to your fleet.

Cloud-based fleet management tools make tracking these fleet costs straightforward, offering real-time insights into asset performance and helping you spot trends early. Regular CPM analysis reveals patterns that can help you time replacements more effectively and improve your fleet's efficiency.

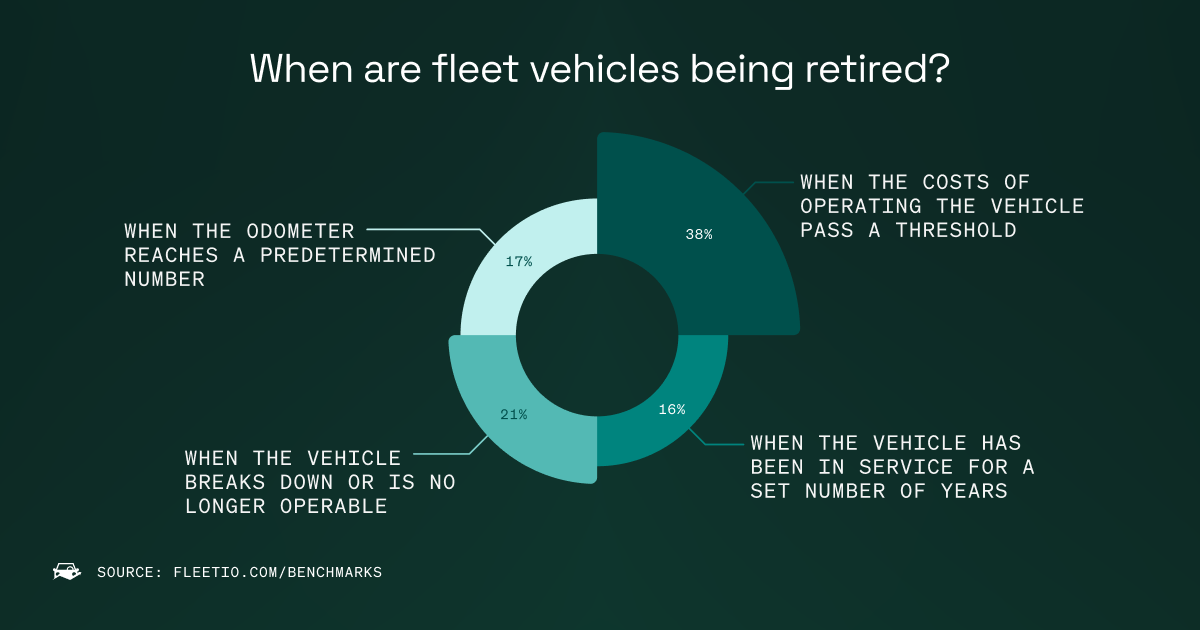

Age and Mileage: Creating clear guidelines

While not as detailed as CPM analysis, setting age or mileage parameters helps create consistent guidelines for lifecycle management. These benchmarks should reflect your specific operation, taking into account factors like asset type, usage patterns and operating conditions. For example, assets handling heavy loads might need earlier replacement than those used in lighter applications.

Consider these parameters as flexible guidelines rather than strict rules. They work best when used alongside service history and other performance metrics to inform your decision-making process.

Preventive Maintenance Tracking: Protecting your investment

A strong preventive maintenance program directly impacts your fleet's TCO. By tracking scheduled service completions, maintenance intervals and service history, you can identify patterns that inform your replacement strategy. Fleet management software helps you maintain detailed preventive maintenance records and analyze service patterns, making it easier to identify assets that are becoming costly to maintain.

Learning from retiring assets: The exit interview approach

Gathering insights from retiring assets helps improve future fleet management decisions. Here are key questions to consider:

Performance Review

- What was the total maintenance investment over the asset's lifecycle?

- How did actual maintenance costs compare to projections?

- What were the most common repair needs?

- How did fuel efficiency change over time?

- What does the service history reveal about long-term reliability?

Operator Feedback

- What worked well for operators?

- Were there recurring comfort or usability concerns?

- Which features would improve functionality?

- How did the asset perform in various conditions?

- What insights from the maintenance history should influence future purchases?

Operational Assessment

- Did the asset meet its intended purpose?

- What modifications could enhance performance?

- How did it compare to similar assets?

- What insights should guide future specifications?

- How did preventive maintenance impact overall performance?

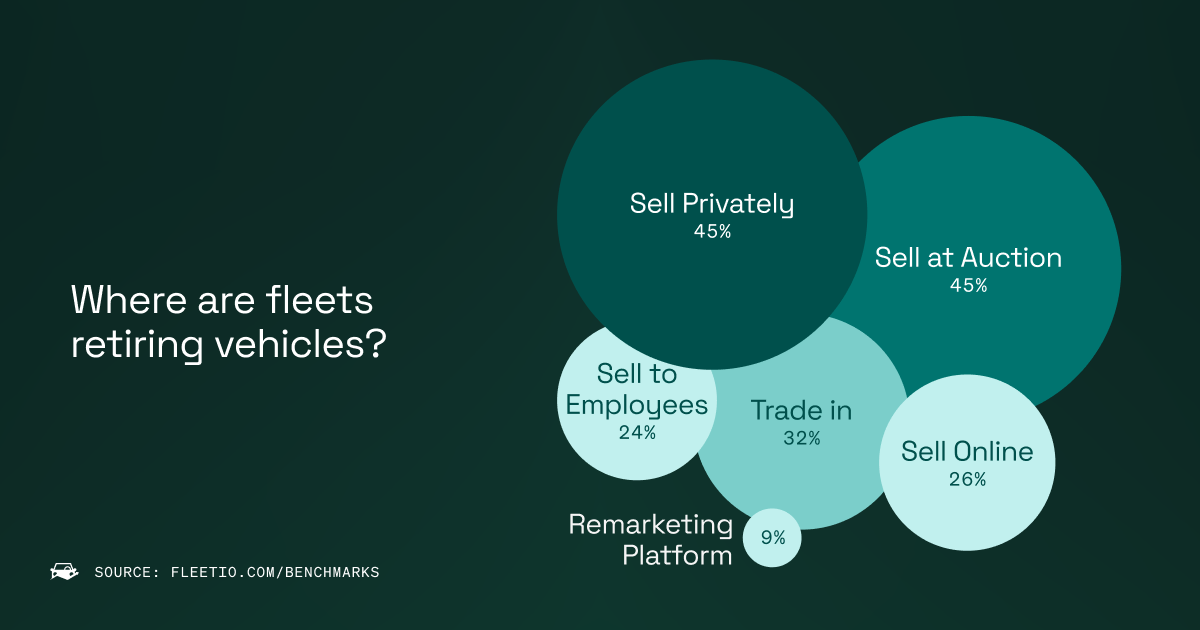

Maximizing value during asset disposal

When it's time to retire an asset from your fleet, your vehicle disposal method affects your total cost of ownership. Private sales often bring the highest returns but require more time and attention. This approach might make sense for specialized or high-value assets where the extra effort yields meaningful returns.

Dealer trade-ins offer an efficient process, especially with established partnerships. While the financial return might be lower than private sales, the simplified process can benefit busy fleet managers looking to maintain optimal lifecycle management.

Auction services work well for managing multiple disposals efficiently. They provide quick turnaround times and market-based pricing, proving particularly useful when you need to cycle out several assets at once.

Know when to let go

Save more and stress less. We built a Vehicle Replacement Calculator to help you balance operating costs and depreciation and replace your assets at the right time.

Get calculatingConsidering electric assets in your fleet replacement plan

As you evaluate replacement options, electric assets present compelling advantages for fleet operators. The benefits extend beyond fuel savings – electric assets typically need less preventive maintenance due to simpler mechanical systems, and many regions offer incentives for adoption.

From an operational perspective, electric assets can deliver improved performance and simplified maintenance schedules. They often provide smoother operation and better acceleration, which can improve operator satisfaction. However, successful integration requires thoughtful planning, particularly around charging infrastructure and route optimization.

The environmental benefits align with sustainability goals and emerging regulations, helping position your organization for the future while supporting current environmental initiatives.

Building an effective fleet lifecycle management strategy

Effective fleet lifecycle management combines careful tracking with flexible planning. By maintaining comprehensive maintenance records and regularly reviewing your strategy, you can optimize your fleet's performance while managing total cost of ownership effectively.

Remember that successful asset replacement isn't just about timing – it's about building an efficient, sustainable fleet that supports your organization's goals while controlling operational costs. Regular evaluation of your fleet management approach ensures you're making informed decisions that prepare your fleet for future needs.