How to Build a Preventive Maintenance Program That Keeps Your Fleet Moving

A preventive maintenance program is the best way for fleets to guarantee uptime, reduce repair costs and lengthen asset lifespan. Managing your fleet preventive maintenance program through software automates service reminders and provides insight into future maintenance tasks.

Jun 4, 2024 | Updated: Jul 3, 2025

12 min read

How to build a vehicle maintenance program that reduces downtime

A strong vehicle maintenance program helps prevent breakdowns, extend asset lifespan, and keep your fleet compliant. Here's how to get started:

-

Understand the difference between preventive and reactive maintenance — Focus on planned service over costly repairs.

-

Set a consistent PM schedule — Base it on time, mileage, or engine hours for tasks like oil changes, inspections, and tire rotations.

-

Track key maintenance KPIs — Monitor uptime, maintenance cost per vehicle, and work order completion rates.

-

Close the loop with communication — Make sure drivers, techs, and fleet managers share real-time updates and issues.

-

Address common challenges — Solve gaps in record-keeping, technician availability, or missed service with the right tools.

-

Use CMMS and telematics — Automate reminders, manage work orders, and catch issues early with connected systems.

Modern fleet maintenance isn't just about fixing vehicles - it's about using systems and data to prevent problems before they happen.

What is a vehicle maintenance program?

A vehicle maintenance program is the processes and guidelines you use to keep your vehicles up and running, so that you can avoid on-the-job incidents and unplanned downtime. This includes regular preventive maintenance as well as any random repairs that may crop up.

However, the most effective automotive fleet maintenance programs focus heavily on preventive maintenance rather than reactive repairs. Preventive maintenance involves scheduled, planned service tasks performed at regular intervals – such as oil changes every 5,000 miles, tire rotations every 6,000 miles, and brake inspections every 12 months. In contrast, reactive maintenance occurs when something breaks down unexpectedly, often resulting in costly emergency repairs and unplanned downtime.

A comprehensive preventive maintenance program typically includes routine tasks like:

- Oil and filter changes

- Tire rotations and pressure checks

- Brake system inspections

- Fluid level checks and top-offs

- Belt and hose inspections

- Battery testing and maintenance

- Scheduled DOT inspections

These preventive maintenance programs fit into the broader scope of fleet management by ensuring vehicles remain roadworthy, compliant with regulations, and operating at peak efficiency—ultimately supporting your fleet's operational goals and bottom line.

Maintenance management that’s actually—"manageable".

Automate alerts, track repairs, and improve uptime—all in one platform.

Take a closer look7 tips for developing a vehicle maintenance program

A strong preventive maintenance program is the first step to reducing downtime and managing a productive fleet. Whether you manage maintenance in-house or outsource your fleet maintenance services to a third party, defining your preventive maintenance program keeps your fleet both proactive and productive. Here are a few ways to take your preventive maintenance program to the next level.

1. Develop a maintenance schedule

Having a schedule for routine maintenance tasks, like oil changes, tire rotations, and brake inspections can help you stay on track with OEM guidelines for maintenance without any severe interruptions to your day-to-day operations.

2. Provide training for your team

Provide training to your drivers and maintenance staff on the importance of regular maintenance and how to identify potential problems. This can help prevent breakdowns and other issues that can impact fleet performance.

3. Maintain records for vehicles

Have detailed records of all services performed, like the date of the task, technician, and any parts or materials used so you can track completion rates, costs and downtime.

4. Monitor performance

Keep track of your vehicle health and record metrics like fuel efficiency and maintenance costs so you can identify trends in your maintenance costs and make adjustments.

5. Set KPIs to track program effectiveness

Establishing key performance indicators (KPIs) is crucial for measuring the success of your preventive maintenance program. Track metrics such as:

- Vehicle uptime percentage — The amount of time vehicles are available for service

- Maintenance cost per vehicle — Total maintenance expenses divided by fleet size

- Work order completion rate — Percentage of scheduled maintenance tasks completed on time

- Mean time between failures (MTBF) — Average time between breakdowns

- Compliance rate — Percentage of vehicles that receive maintenance within scheduled intervals

These metrics help you identify areas for improvement and demonstrate the value of your preventive maintenance investments.

6. Improve processes and compliance with software

Fleet management software like Fleetio can help you automate your maintenance process, including scheduling maintenance tasks, tracking maintenance records, and generating reports.

7. Close the loop with communication and accountability

Effective communication between drivers, maintenance teams, and fleet managers is essential for a successful preventive maintenance program. Establish clear protocols for:

- Reporting vehicle issues or concerns

- Updating maintenance status and completion

- Sharing real-time vehicle condition updates

- Escalating urgent repairs or safety concerns

Creating accountability measures ensures that everyone understands their role in maintaining fleet health and that maintenance tasks don't fall through the cracks.

The maintenance playbook every fleet manager needs

Proven insights to minimize breakdowns, improve uptime, and keep your fleet moving forward.

Don't miss outChallenges to effective preventive maintenance programs

Even with the best intentions, many fleets struggle to maintain consistent preventive maintenance programs. Understanding these common challenges is the first step toward overcoming them and building a more effective maintenance strategy.

Common pain points fleets face

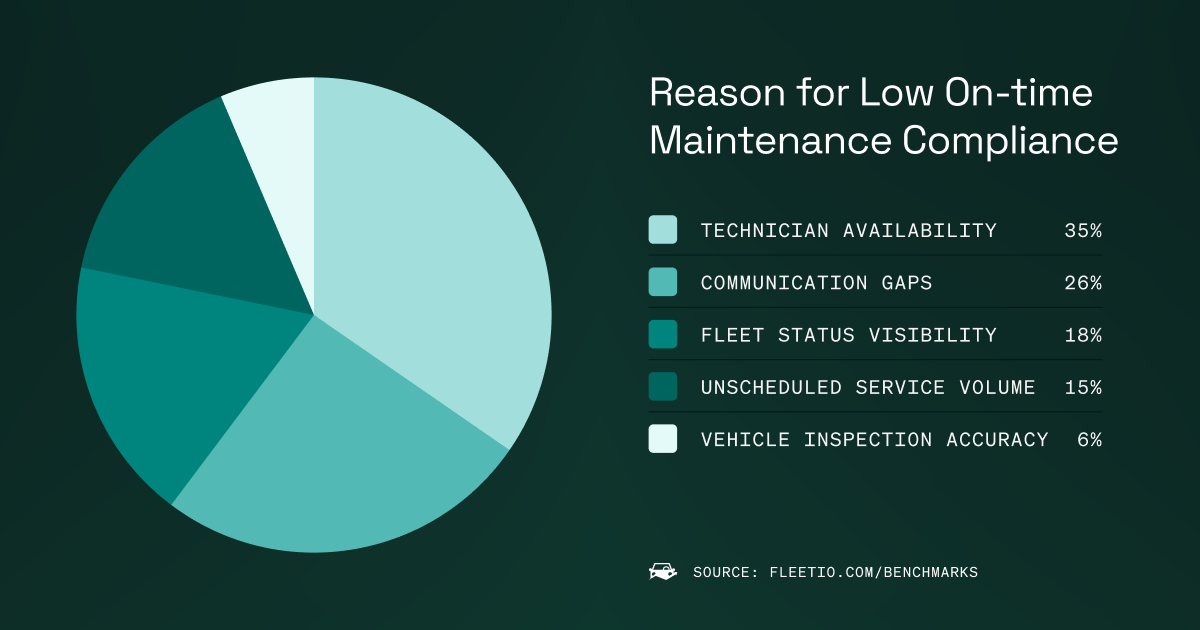

Technician availability remains the top challenge, according to surveyed operations leaders. Limited technician capacity can create bottlenecks that delay scheduled maintenance and push vehicles past their optimal service intervals.

Missed maintenance tasks often occur when fleets rely on manual tracking systems or paper processes. Without automated reminders, it's easy for routine maintenance to slip through the cracks, especially when managing large fleets with varying service schedules.

Poor record-keeping creates visibility gaps that make it difficult to track maintenance history, identify recurring issues, or demonstrate compliance during audits. Incomplete or scattered records can also lead to duplicate services or missed warranty claims.

Communication gaps between drivers, maintenance teams, and fleet managers can result in delayed issue identification and resolution. When vehicle problems aren't reported promptly, minor issues can escalate into major repairs.

Lack of real-time visibility into fleet status makes it challenging to prioritize maintenance tasks, allocate resources effectively, or make informed decisions about vehicle deployment.

These challenges highlight why manual maintenance management systems often fall short and why many fleets are turning to automated solutions to improve their preventive maintenance programs.

Creating stronger vehicle maintenance programs with CMMS

Though the success of any fleet hinges on asset uptime, many fleets have trouble adhering to their preventive maintenance programs. This challenge is usually caused by an inefficient fleet management system. Fleets that still use paper processes or a fleet maintenance sheet to manage preventive maintenance often have trouble staying on top of tasks and keeping an organized system of record.

An unorganized preventive maintenance program can cause fleet vehicles to miss routine maintenance. Not only can this lead to unexpected downtime, but unplanned repairs can have negative impacts on your fleet’s bottom line.

To maximize efficiencies and streamline preventive maintenance tasks, many fleets are leveraging a modern fleet management system or a fleet-specific CMMS (computerized maintenance management system). Creating and managing preventive maintenance schedules in software allows you to set service reminders, view repair history and manage all fleet maintenance in an organized system.

Using an organized, flexible system to manage service allows you to standardize service intervals, stay in regulatory compliance and follow OEM guidelines to meet warranty standards. Instead of worrying about unplanned repair costs and trying to play catch up from unexpected downtime, fleet management software gives you peace of mind by helping you automate preventive maintenance tasks.

Integration with telematics and inspection data

Modern CMMS platforms can integrate with telematics systems and electronic vehicle inspection data to create a more proactive maintenance strategy. This integration enables:

- Real-time vehicle diagnostics and fault code monitoring

- Automatic work order creation based on telematics alerts

- Predictive maintenance scheduling based on actual vehicle usage patterns

- Integration of inspection results to identify maintenance needs before they become critical

Creating and managing preventive maintenance schedules in software allows you to set service reminders, view repair history and manage all fleet maintenance in an organized system.

Using an organized, flexible system to manage service allows you to standardize service intervals, stay in regulatory compliance and follow OEM guidelines to meet warranty standards. Instead of worrying about unplanned repair costs and trying to play catch up from unexpected downtime, fleet management software gives you peace of mind by helping you automate preventive maintenance tasks.

Set service reminders based on odometer readings

Since fleet managers are constantly juggling tasks, some items on the to-do list can slip through the cracks. Creating service reminders for preventive maintenance tasks is the best way to ensure vehicles receive on-time service.

While service reminders can be scheduled based on calendar date or engine hour intervals, many manufacturers recommend maintenance based on odometer readings. Because of this, fleet managers need an efficient way to accurately track mileage on each vehicle.

Fleets that still use paper processes to manage maintenance often have difficulty tracking mileage and engine hour intervals. Managers only receive updates from their drivers when they return to the office. These infrequent updates often result in assets being overdue on preventive maintenance.

Fleet management software enables users to receive accurate odometer updates in real-time to trigger service reminders in their preventive maintenance program. Instead of manually tracking odometer readings and calculating when service is due, Fleetio automates these processes to help you start maintenance on time.

Operators can update odometer readings and engine hour intervals through a fleet app on their phone, or fleets can take advantage of telematics integrations to receive instant updates from their telematics device in fleet management software.

Setting service reminders allows users to keep up with their preventive maintenance program with mobile notifications. Email or push notifications are sent to managers before service is due to ensure maintenance is performed and assets stay in good condition.

Pro Tip

Standardize service reminders and bulk manage preventive maintenance tasks across your fleet with Service Programs.

Leverage eDVIR results to refine your preventive maintenance program

A key part of a proactive preventive maintenance program is routinely monitoring asset condition. While preventive maintenance schedules ensure your assets are receiving regular service, it’s important to regularly inspect assets to identify any underlying issues.

Results from paper vehicle inspections, like Driver Vehicle Inspection Reports (DVIR), often aren’t communicated quickly. To eliminate bottlenecks in the maintenance process, many fleets are streamlining the inspection process with electronic vehicle inspections.

Electronic vehicle inspections enable operators to conduct fast, thorough inspections on a mobile device. Results are uploaded instantly into fleet management software, alerting managers to any issues.

Fleet managers can leverage inspection results to create and assign work orders for preventive maintenance to begin quickly. By taking simple, proactive measures, you could save your fleet from countless hours of downtime and more expensive repairs.

What’s your preventive maintenance system look like?

Imagine a system that schedules PMs, tracks repairs, and keeps you in the loop—hands free. That’s Fleetio.

Schedule a time to chatPredict future preventive maintenance based on service history

In addition to automating processes to streamline your preventive maintenance program, it’s important to carefully analyze your vehicle service history to monitor productivity and asset health. Tracking service history allows you to spot trends across your fleet and make the best decisions for its future.

Maintenance log software stores comprehensive service logs for all your assets making it easy to view past completed service. This information can help your maintenance team understand an asset’s past and not overlook or repeat any repairs.

Having a complete look at your fleet’s service history allows you to analyze issues across your fleet. With configurable software like Fleetio, you can sort service history by task to identify overarching issues with a certain part across assets.

Automatically recording service history also increases efficiency for fleets who outsource maintenance. Fleetio’s Maintenance Shop Integration allows fleet managers to approve maintenance electronically to speed up the repair process. All service is recorded automatically to eliminate data entry and provide better visibility into completed repairs.

Bulk manage preventive maintenance tasks with service programs

Preventive maintenance tasks vary across different types of assets, and creating service schedules for every vehicle in a fleet is time-consuming. To simplify the process, service programs enable users to create and manage service reminders across assets to save time and standardize their preventive maintenance programs.

Key CMMS features for fleet maintenance

Beyond basic service reminders, modern CMMS platforms offer comprehensive features including:

- Reporting dashboards that provide real-time visibility into maintenance metrics, costs, and fleet health indicators

- Parts inventory management to track stock levels, automate reordering, and ensure parts availability when needed

- Work order management to create, assign, and track maintenance tasks from start to finish

- Asset history tracking to maintain comprehensive records of all maintenance activities and repairs

- Compliance reporting to ensure adherence to DOT regulations and OEM warranty requirements

How Fleetio does maintenance

With Fleetio’s service programs, you can apply a set of fleet maintenance checklists to multiple vehicles at a time. Having a way to organize service tasks and attribute them to specific assets in bulk eliminates hours of tedious data entry.

How we take on common challenges

- Address technician availability — Automated scheduling and work order management help optimize technician workflow and reduce scheduling conflicts

- Eliminate missed maintenance — Automated reminders and real-time tracking ensure no maintenance tasks slip through the cracks

- Improve record-keeping — Centralized digital records provide complete visibility into maintenance history and compliance status

- Bridges communication gaps — Real-time notifications and mobile access keep all stakeholders informed and connected

Fleets using Fleetio typically see significant improvements in maintenance compliance rates, with many achieving 85%+ on-time completion of scheduled maintenance tasks. In our State of Fleet Management Survey, we found that there was a direct correlation between Fleetio customers and on-time compliance: The automated reminder system alone helps fleets reduce emergency repairs by up to 40%, while comprehensive reporting capabilities enable better budget forecasting and resource allocation.

Though creating preventive maintenance programs may seem like an uphill battle, the use of Fleetio can streamline and expedite the process, so you can spend less time manually managing maintenance and more time analyzing and improving your fleet. Automating service reminders across your fleet with the help of service programs ensures your fleet remains in compliance and reduces downtime.

Senior Fleet Content Specialist

As a Senior Fleet Content Specialist at Fleetio, Peyton explores the voices and experiences that shape fleet operations. She focuses on how fleet professionals adopt technology, improve efficiency and lead their teams to bring clarity and context to the challenges happening across the industry.

View articles by Peyton Panik

Director of Fleet Content, Fleetio

Zach Searcy is the Senior Content Marketing Manager at Fleetio with more than 5 years of experience in the automotive and fleet industries. His content creation days started in middle school when he and his friends began filming lightsaber battles to upload to a new website: 'YouTube.'

LinkedIn|View articles by Zach SearcyReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304