How to Calculate the Total Cost of Ownership for Your Fleet

Fleet management costs and more specifically, total cost of ownership (TCO) measures the true cost of a vehicle, including all associated expenses like acquisition and maintenance.

Nov 15, 2024

7 min read

TL;DR: What exactly is Total Cost of Ownership?

Fleet Total Cost of Ownership (TCO) is the full sum of expenses tied to operating a vehicle over its lifecycle, including acquisition, maintenance, fuel, depreciation, downtime, licensing, and administrative costs. Calculating TCO helps fleet managers plan budgets, decide when to replace vehicles, and identify cost-saving opportunities.

Key TCO cost categories:

- Acquisition and depreciation - Initial purchase cost and loss of value

- Fuel and maintenance - Largest and most variable ongoing expenses

- Downtime and admin - Often overlooked but critical to efficiency

- Licensing and capital costs - Hidden expenses that impact long-term ROI

TCO is unique to every fleet. Use your own data for accuracy, and benchmark against similar fleets to evaluate performance and improve decision-making.

What is Fleet TCO?

Total Cost of Ownership (or TCO) is the collection of all expenses that go into operating a fleet asset. An accurate TCO calculation for each of your fleet assets can help you project budgeting needs and determine the best time to replace vehicles in your fleet. It’s important to measure TCO carefully because a misleading calculation can provide false insight into the cost of your assets and lead to damaging financial decisions.

Turn fleet costs into fleet savings

Learn how managing your TCO can optimize asset usage, reduce costs, and better inform your decision making.

Download your copyHow do you calculate fleet total cost of ownership?

Ernst & Young (E&Y) conducted an in-depth study on TCO and determined the major cost categories for this measurement include cost of capital, maintenance, asset depreciation, licensing and vehicle administration. In the study, E&Y chose to measure TCO in cost per mile (CPM).

Calculating TCO

To calculate TCO, you need to add all of the costs associated with the operation of your vehicle. The formula to calculate TCO is Acquisition Costs + Admin/Operating Costs + Depreciation + Downtime Costs.

Cost of Capital

Capital costs are the most overlooked cost metric, particularly for small- to medium-sized businesses who purchase assets using cash. When businesses acquire assets without needing financing, it is often assumed this does not need to be included in the TCO calculation. But, contrary to that belief, businesses must account for this opportunity loss of money, in other words, the loss of a potential greater return had the money been used differently.

The E&Y study found that economies of scale influence total cost of ownership. The greater the fleet size, the lower the TCO per unit (if measuring by cost per mile). A couple reasons this is true is because larger fleets tend to have greater negotiating power with dealerships and realize more maintenance efficiencies.

Smaller sized fleets could use economies of scale to their advantage by being more intentional through purchasing equipment more efficiently, realizing better resale values, improving cost forecasting and using more knowledgeable maintenance technicians.

Vehicle Maintenance

The cost to maintain a vehicle or asset increases over its lifetime. In fact, E&Y found maintenance costs to increase exponentially as assets age, with the greatest increases happening in the first and seventh year of the asset. According to a study by Automotive Fleet, repair costs average $14.80 per vehicle when in service one year and increase to $68.62 per vehicle after being in service for over three years. Many fleets may choose to sell a vehicle after its seventh year of service while it still maintains some of its value.

Of course, age is not the sole predictor of maintenance costs. The quality and consistency of asset maintenance also affects its cost over time. The cost of downtime is recommended to be included in TCO calculations as well.

Pro-Tip

Choose a trusted maintenance service provider to ensure maintenance quality during the lifetime of your vehicles.

Fuel Usage

As fuel is the largest budget item for many fleets, tracking fuel costs and consumption is essential to getting an accurate picture of your TCO. Each of your assets requires some form of fuel to operate, and the costs can vary wildly depending on the vehicle type, fueling location, and of course the fluctuating fuel economy.

While fuel might seem like an inevitability, you can identify cost-savings opportunities simply by tracking your fuel expenses. A full picture of your fleet’s fuel spend will give you insights into assets that are underperforming or help you identify potential situations of fuel theft.

Make sense of your—cents.

Your fleet’s costs shouldn’t be a mystery. Get a clear view of your Total Cost of Ownership, track expenses, and uncover ways to optimize spending—all in one place.

See how it worksAsset Depreciation

The value of your asset decreases over time as it undergoes greater wear and tear. Companies often calculate depreciation under the assumption it will be valued $0 at the end of its predicted useful life. Typically, however, assets can be valued at 20 percent of its purchase price after five to six years of useful life and 10 percent of its purchase price after ten years.

When purchasing new assets, consider purchasing those with lower depreciation rates so that they maintain a greater residual value in the future once you’re ready to sell.

Licensing and Vehicle Administration

Don’t forget to incorporate your licensing and vehicle administration costs in your TCO calculation. These costs may vary from one fleet to another. Carefully consider all associated costs in your calculation.

For reference, E&Y calculated the average total cost of ownership based on cost category and type of vehicle. Their findings are shown in the table below:

| Cost Categories | Class 8 tractors ($/mi) | Class 6 & 7 trucks ($/mi) | Reefer trailers ($/mi) | Dry van trailers ($/mi) |

| Financing | 17.0 | 28.5 | 9.1 | 8.5 |

| Maintenance | 16.2 | 15.5 | 6.2 | 10.0 |

| Administration | 3.0 | 2.9 | 0.6 | 1.6 |

| Licensing | 2.0 | 2.7 | N/A | N/A |

| Total costs | 38.2 | 49.7 | 15.9 | 20.0 |

Source: Stella, Donna, et al. Own or Lease: Are You Making the Right Choice for Your Truck Fleet?, Ernst & Young, 2012

Understanding fleet management Cost per Vehicle

Calculating the cost per vehicle provides fleet managers with insights that can be used to streamline operations and make informed budgeting decisions. By evaluating the Total Cost of Ownership (TCO) for each asset, you gain a clear understanding of the financial impact of every vehicle in your fleet.

It helps you identify patterns in expenses, highlight cost-saving opportunities and determine whether individual assets are contributing to or draining your fleet’s efficiency. With this insight, you can:

- Enhance Budget Accuracy: understand where your budget is going and allocate resources more effectively across your fleet

- Optimize Asset Utilization: recognize underperforming vehicles and reduce unnecessary expenses by addressing issues like overuse or downtime

- Plan Proactively: forecast future expenses such as maintenance, fuel or replacements, allowing for a more strategic approach to fleet management

- Support Business Cases: use detailed cost data to justify investments in fleet improvements, such as upgrading vehicles or implementing fleet management software

By focusing on TCO, fleet managers can ensure each asset supports operational efficiency and contributes to the overall success of the organization.

Tips for calculating Fleet TCO

Use numbers specific to your fleet

While it’s tempting to calculate your TCO using another fleet’s metrics, the result can be misleading. One fleet may vary from another in terms of economy of scale, number of assets, quality of maintenance, asset use and more, which can affect TCO calculations.

Also, using numbers from another fleet can introduce bias since a person may choose metrics that seem aligned with their fleet based on what they think or would like their metrics to be but may not be in reality.

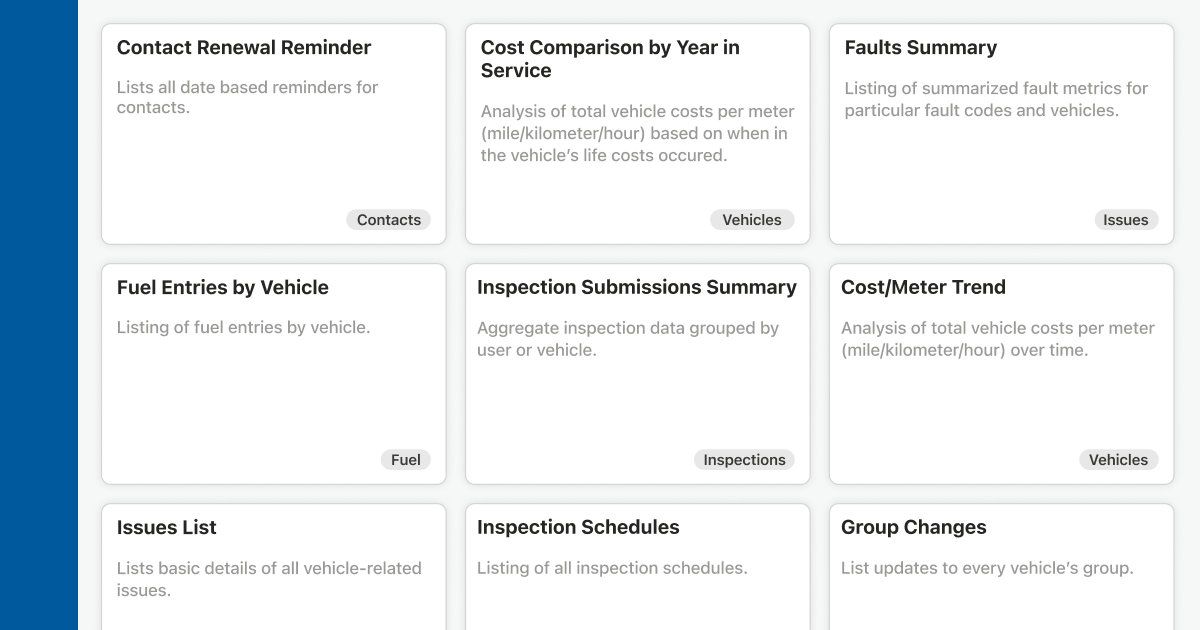

If you have a fleet maintenance software, all of your fleet data will be available here for number crunching.

Benchmark to similar fleets

While it’s important to use your own numbers when calculating TCO, it is a good practice to compare your TCO to a similar fleet’s TCO. This can give you a solid idea into how your fleet is performing and whether you are keeping up with your peers.

How does your fleet compare to the competition?

Benchmark your fleet’s performance against industry standards. Use these insights to find areas for improvement and stay ahead of the pack.

Download your reportFleet software allows you to instantly calculate the TCO of each asset in your fleet. Start a free trial of Fleetio to unlock insights into your fleet’s costs of operation.

Jessie Robinson

Director of Fleet Content, Fleetio

Zach Searcy is the Senior Content Marketing Manager at Fleetio with more than 5 years of experience in the automotive and fleet industries. His content creation days started in middle school when he and his friends began filming lightsaber battles to upload to a new website: 'YouTube.'

LinkedIn|View articles by Zach SearcyReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304