5 Steps to Building a Heavy Equipment Maintenance Schedule

We've all seen it happen. You have a big project on a tight timeline and a critical piece of heavy equipment breaks down, leading to project delays, frustrated teams and blown budgets. If you had a solid equipment maintenance schedule, you could've kept your fleet running smoothly and the project on track.

Mar 27, 2025

4 min read

Maintaining construction equipment isn't as straightforward as maintaining standard fleet assets. You rely on high-dollar assets in a harsh environment to drive a profit.

Downtime isn't an inconvenience. It's expensive.

Building a heavy equipment maintenance schedule

With preventive maintenance, you can avoid unplanned downtime almost entirely. Here are a few best practices to help you build reliable maintenance schedules.

1. Establish your preventive maintenance plan

Before anything else, you need an equipment preventive maintenance (PM) plan to communicate to your team. To get your equipment maintenance schedule set up:

- Identify service intervals based on engine hours, usage cycles or OEM recommendations

- Categorize maintenance tasks by frequency (daily, weekly, monthly and seasonal checks)

- Record maintenance history to ensure compliance and map out future schedules

- Create a maintenance calendar and implement a system to send reminders for upcoming tasks

Pro-Tip

Construction equipment management software simplifies preventive maintenance tracking by syncing real-time data from your equipment, making it easier to identify budding issues while away from the job site.

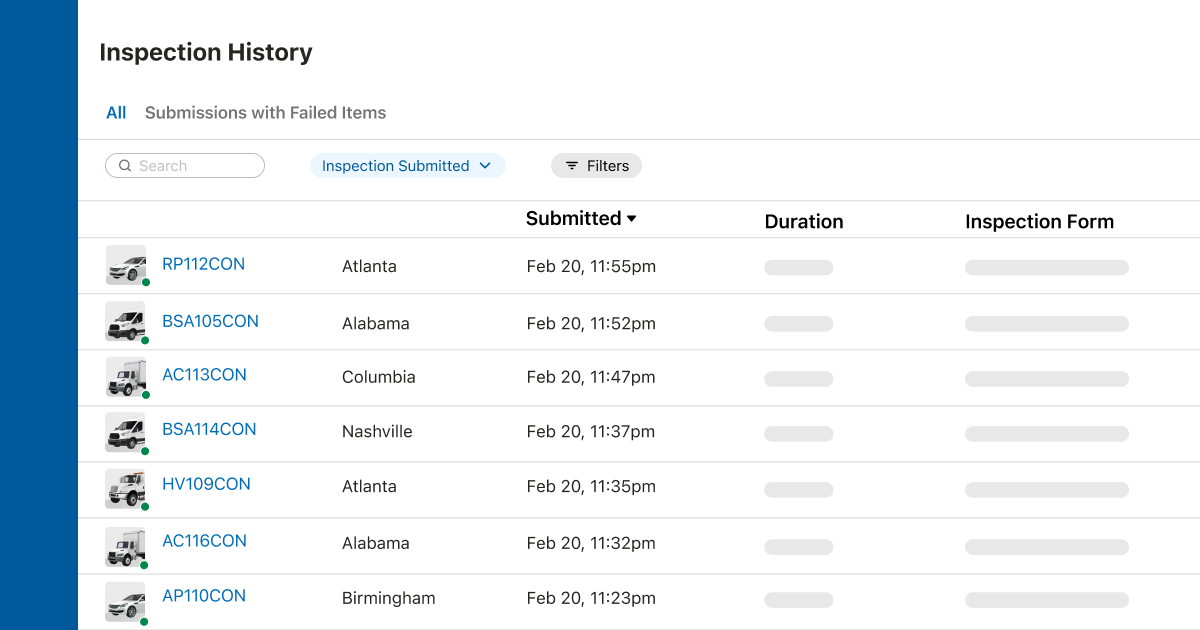

2. Conduct regular equipment inspections

Daily equipment inspections help you spot issues before they escalate. Heavy equipment is often exposed to harsh conditions, and daily checks can reveal early signs of damage or wear.

3. Monitor equipment status with telematics

Without a telematics system, you would have to visit every single job site to know the performance of your equipment. Telematics systems provide a real-time view of your fleet's health, allowing you to make informed decisions and know when an asset is due for service.

4. Keep detailed service records

Having a clear maintenance history for each piece of equipment helps you stay organized and make better decisions about repairs, replacements and budgeting.

A few best practices when it comes to service records:

- Keep a log of all completed maintenance

- Track parts usage & inventory to avoid stockouts

- Analyze trends over time to surface larger issues

- Keep digital records for quick and easy reference

Pro-Tip

Use your maintenance logs to spot patterns, avoid repeat service, and address minor issues before they become more significant.

5. Know your total cost of ownership (TCO)

Understanding your construction fleet operating costs helps you make informed decisions around budgeting and replacement schedules.

Leave downtime in the dust

Keep your heavy equipment maintenance on track with the right tools. From the job site to the shop, our Caterpillar VisionLink and John Deere Operations Center integrations give you real-time updates no matter where your assets are parked or put to work.

Join other construction fleetsHeavy Equipment Maintenance Schedule Example

If you're just getting started, you shouldn't stress over a complicated maintenance schedule. We've found that even a simple list of tasks can help improve any maintenance program.

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Inspect fluid levels, tires, brakes and lights. Record engine hours. |

| Weekly | Inspect hydraulics, tracks and electrical systems. Check air filters. |

| Monthly | Perform oil changes, coolant checks, and safety system tests. |

| Quarterly | Comprehensive inspection of engine, suspension and undercarriage. |

| Seasonal | Inspect heating/cooling systems. Prepare for extreme temperatures. |

How Fleetio simplifies heavy equipment maintenance

Setting a maintenance schedule is one thing; actually sticking to it is another. Fleetio gives you the tools you need to anticipate maintenance needs, avoid costly breakdowns and keep projects running smoothly.

Keep projects on schedule with automated maintenance triggers Improve communication between field operators and maintenance teams Make data-driven decisions to reduce downtime and extend equipment lifespan

Fleet management impacts so many different levels of the organization, from cap-ex to budgeting, accounting, safety and insurance. Bringing in a tool that brings all the data into one centralized location to make informed decisions and help guide our business was critical. Chloe Gentry, Cherrylake

Fleetio simplifies heavy equipment maintenance by providing a comprehensive, real-time view of your construction fleet's health. With Fleetio, Cherrylake cut their repair costs from $500k a year to $350k despite adding 15% more assets to their fleet.

Fix it before it breaks

Book a quick demo and see firsthand how Fleetio helps construction crews like yours stay on top of maintenance and your projects moving forward.

Let's connect

Content Marketing Specialist

Laura Flowers is the Content Marketing Specialist at Fleetio. When she’s not blogging, you can find her reading on the couch with her cat or in the studio tap dancing.

LinkedIn

Director of Fleet Content, Fleetio

Zach Searcy is the Senior Content Marketing Manager at Fleetio with more than 5 years of experience in the automotive and fleet industries. His content creation days started in middle school when he and his friends began filming lightsaber battles to upload to a new website: 'YouTube.'

LinkedIn|View articles by Zach SearcyReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304