How Fleets can Overcome Change Management Challenges

Change management is often a complex — perhaps even frustrating — process for any business, but it can be especially tricky for those managing fleets. That’s why we’re taking a look at common change management challenges and tips for overcoming them.

Mar 11, 2025

6 min read

Change management may not get top billing over managing fleet drivers in a fleet manager's job description, but it’s a key factor in keeping your operation running smoothly. Change management in fleet encompasses a pretty wide range of things, like rightsizing — in labor, assets and scope of business — standard asset replacement and procurement, implementing fleet and other business solutions and, generally, process and workflow changes.

Change management can be a less-than-fun aspect of the job, and the mobile nature of fleet makes it that much more challenging — and not just because you’ve got to pin everyone down at some point to explain what is changing, why and how it will affect their day-to-day responsibilities. Let’s take a look at a few of the top challenges when it comes to managing change for your fleet.

The Human Element

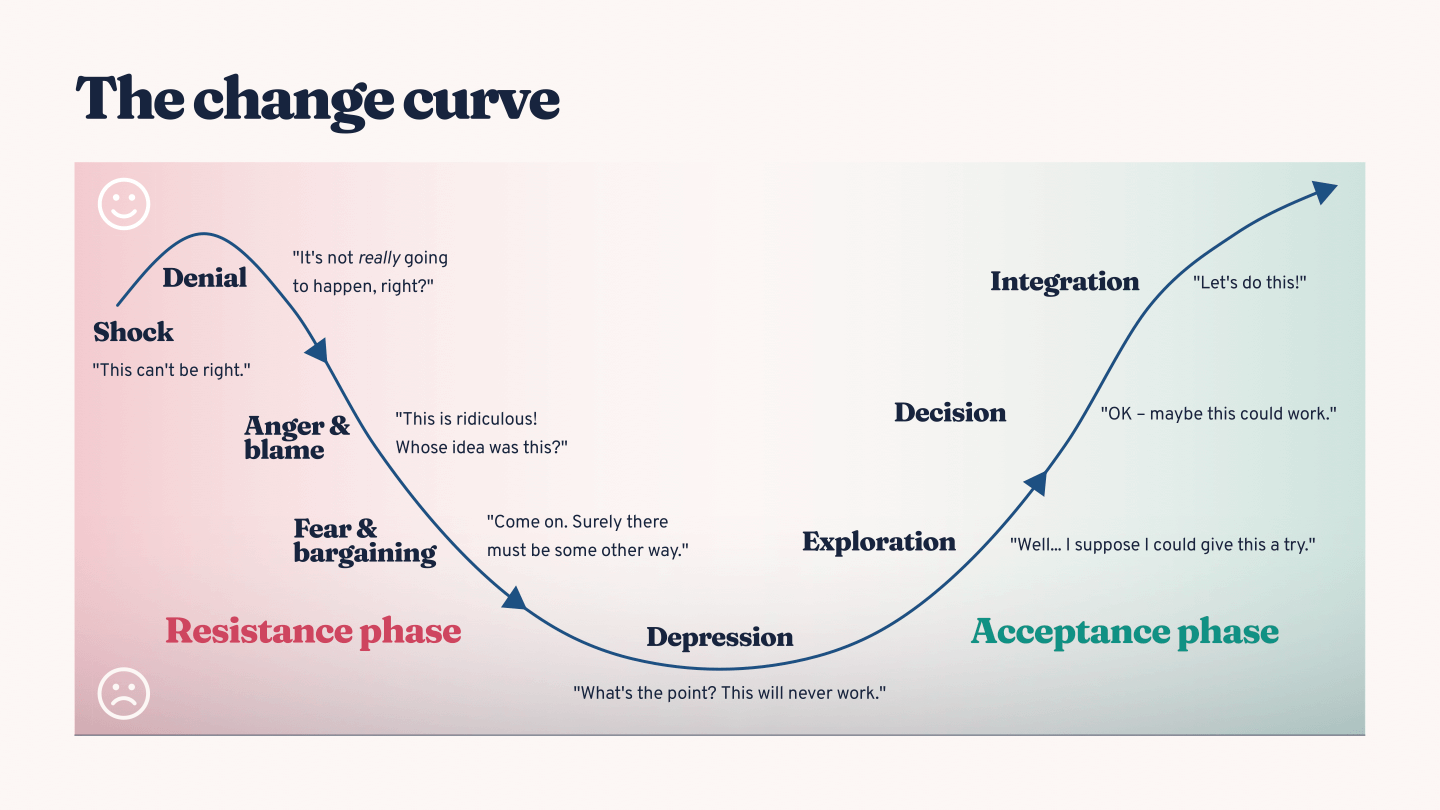

There is often a natural level of resistance to change, especially if the change is — or is perceived as — disruptive, challenging to adapt to or seems unnecessary. Accounting for the human element in change management can make or break the successful implementation of the change in question, which means you’ve got to move your team from resistance to acceptance as quickly as possible. Let’s break it down.

1. Failure to Communicate

While you may see a need for change to improve an aspect of or, heck, even your whole operation, based on high-level data insights, your drivers and technicians could be in the “if it ain’t broke, don’t fix it” mindset. This means it’s important to clearly explain why the change or changes are happening and what the benefits are. Otherwise, you may run into misunderstandings and pushback. Plus, ineffective communication to your team could cause feelings of being blindsided or out of the loop, which can lead to disengagement.

Solution

Clearly communicate the reason for the change, including how it will affect employees’ daily activities, what they can anticipate during the rollout of the change and what benefits are expected. Engage in feedback so you can address specific concerns. One fleet manager explains that when his team adopted a new fleet solution, “the change management was awful at the beginning, but now that they've actually seen how it's saved them in many situations [...] we're getting that message out to the fleet.”

2. Resistance to Change

While we touched on this earlier, it’s worth taking a deeper look into resistance to change and some of the causes. Drivers and techs may be resistant to new processes or technologies due to things like fear of job displacement, increased workloads, lack of familiarity with new systems or software or even just not wanting to break from what’s become routine. Introducing change can trigger uneasiness or a perceived loss of control.

Solution

Once you’ve determined a change needs to be made, get your team involved early. Ask questions and seek feedback around how they think the change might affect them or their job so you can determine the best way to roll out the change for minimal pushback and workflow disruptions.

3. Operational Disruptions

Since we’re already on the topic of disruptions, let’s talk a little more about it. Any major change — and even some not-so-major changes — can cause both expected and unexpected disruptions and, if you don’t have a solid plan in place, the transition period can cause increased downtime and/or general productivity loss. This can prove frustrating for employees who just want to get their job done, and frustrated employees can quickly become disengaged and at risk of quitting. Not the best situation, for sure.

Solution

Implement changes gradually and strategically to reduce disruptions. Improving communication in your fleet can help with this, as it allows employees to raise issues which you can quickly address to keep the change implementation on track. The back and forth with your team during a change roll out also has the added benefit of increasing employee buy-in and helping ensure the change is making a positive impact.

Tips from a Fleet Manager

Implementing new fleet technologies isn’t always the easiest thing to do. That’s why we talked with Tom Rowlings, Assistant Fleet Manager, City of Cambridge, to learn the steps he took for successful software adoption.

Check it outHigh-level Complications

Dealing with the human element in change management isn’t the only hurdle to overcome. There are some high-level concerns that should be addressed, whether that’s cost, leadership buy-in or preparing the team to work with more advanced technologies.

4. Cost Concerns

Now, I won’t say budgets or budgetary constraints are everyone’s nightmare, but I’m willing to bet it’s a subject that can be categorized, at the very least, as “not one’s favorite.” But change can come with a hefty price tag, especially when talking about implementing a new technology, like a fleet maintenance or optimization platform or electrified assets. Fleets have to balance investments with their budgets, which can lead to a phased or delayed rollout that compounds the complications of change management.

Solution

ROI is a — nay, the — metric to present when it comes to advocating for a costly change, so finding out answers to questions like “how soon can we recoup our investment,” “when can we expect to see returns/savings after implementation” and “what is the projected return/savings on a quarterly or yearly basis once the change is in place”?

5. Leadership Buy-in

Ah, yes. The flipside of employee buy-in: leadership buy-in, which can be just as hard to gain. Fleet managers may struggle to get support for necessary technology or process upgrades. Unaligned priorities — between a sustainability-driven C-suite and a cost-focused fleet manager, for instance — can derail change initiatives. Not only do you need to ensure leadership is fully committed to the transition, but you also have to set expectations for things like fleet-wide change adoption and ROI.

Solution

Effective communication across leadership groups is often a hurdle, so on top of the numbers, it’s important to present your case for why the change is needed, and even how it can tie into other initiatives through money saved, time saved or profitability enhancements.

6. Technology, Training and Upskilling (oh, my!)

Moving toward using advanced technologies, like electric vehicles (EVs), autonomous vehicles (AVs), digital fleet solutions or other automated systems requires upskilling staff to some degree. Drivers and techs may need training on EV operation, inspections and/or maintenance, and legacy systems, like outdated dispatch software, for instance, may not play nice with more modern fleet management tools.

Solution

Provide ongoing training and support. Take advantage of onboarding packages, continued customer success offerings and advanced technology certifications and/or training for drivers and technicians. Set milestones if needed, and follow up with your team to see what additional support they might need.

Measure and Adjust

Once you’ve made a change to your operation, there’s also the aftermath of implementing that change. Measuring how the change has affected your operation is a must so you can understand what’s going right, what’s going wrong and how to make improvements going forward.

Establish key performance indicators (KPIs) applicable to the change, such as lower fuel costs, uptime improvements or PM compliance improvements. Without doing this, it can be rather hard to know if the change or changes are working. And, sure, quantifying the benefits of change may take a little time, but in the long run it can justify the change to stakeholders while highlighting operational benefits.

Ready to manage everything, everywhere, all at once?

Alright, alright, maybe not everything, but definitely your fleet — from assets to drivers, technicians to parts inventory and so much more.

Get after it

Senior Fleet Content Specialist

As a Senior Fleet Content Specialist at Fleetio, Rachael Plant uses her near decade of industry experience to craft practical content aimed at helping fleet professionals tackle everyday challenges with confidence.

LinkedIn|View articles by Rachael PlantReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304