Build a Safer Fleet: Your 2025 Safety Program Guide

Fleet safety matters – but without clear processes, even experienced teams fall short. This guide shows you how to build a proactive safety program that protects your drivers, assets and operations in 2025 and beyond.

Aug 6, 2020 | Updated: Jun 17, 2025

12 min read

Key takeaways from this guide

- Compliance Gap Exposes Fleet Risk: Fewer than one in twenty fleets achieve full maintenance compliance, leaving the rest vulnerable to accidents, downtime and soaring costs. Our first section lays out the survey findings and BLS injury data so you can see exactly why closing this gap can’t wait.

- Unified Safety Program Slashes Crashes: An integrated framework of training, inspections and telematics cuts collisions, claims and fines in a single stroke. Keep reading to learn the core pillars of a modern fleet-safety program and the tangible wins they deliver.

- Four-Step Plan Sustains Safety Culture: Clear rules, mobile inspections, assignment tracking and in-cab tech keep safety improvements alive long after rollout. The article walks you through each step, compares tools and highlights KPIs so your program keeps paying off.

Jump to a topic

According to our 2025 State of Fleet Management survey, only 5% of fleets achieve near-perfect maintenance compliance. Many hover below 75%, exposing them to higher accident risks and costly downtime.

These gaps in compliance highlight a deeper issue: without a formalized safety strategy, even experienced fleets are vulnerable to preventable risks. That’s where a fleet safety program comes in.

What is a fleet safety program?

A fleet safety program is a comprehensive set of fleet safety policies, procedures and practices aimed at ensuring the safety of all vehicles and drivers within your fleet. A comprehensive program typically includes driver training, regular vehicle maintenance, safety inspections and adherence to legal regulations.

Objectives of a fleet safety program

- Reduce Accidents: Implement safety protocols and training programs to minimize collisions and other incidents on the road

- Improve Driver Behavior: Promote safer practices such as reduced speeding and cautious driving

- Maintain a Safe Working Environment: Create a culture of safety that prioritizes the well-being of drivers and other employees

- Lower Insurance Costs: Reduce claim frequency, which may lead to lower insurance premiums over time

- Ensure Regulatory Compliance: Adhere to industry regulations and standards, such as DOT requirements

- Extend Vehicle Lifespan: Keep vehicles in good condition, reducing wear and tear and extending their usable life

Build a safety program everyone can buy into

Do your safety programs and inspection routines feel dead out of water. Rebuild and bring them to life with mobile inspections, automated alerts and full maintenance tracking — all in one place.

Get your safety program back on trackWhy is a fleet safety program important?

A fleet safety program is crucial for reducing risks and protecting both drivers and assets. According to the Bureau of Labor Statistics, transportation incidents were the leading cause of all workplace deaths – responsible for 37% of all reported cases.

And there are many more statistics like that in their 2023 report:

- Truck-transportation firms logged 3 OSHA-recordable injuries for every 100 full-time employees.

- Heavy- and tractor-trailer operators suffered 823 fatal injuries, the highest of any single occupation.

- Automotive repair & maintenance shops reported 2 OSHA-recordable cases per 100 workers, and 163 mechanic fatalities on the job.

- Landscaping services tallied 2.9 recordable injuries per 100 workers.

- The construction sector recorded 1,075 fatalities; more than one-fifth (240) were transportation-related.

By implementing safety protocols and providing regular training, companies can significantly lower the likelihood of accidents and potentially-dangerous outcomes. Plus, a strong safety program helps reduce costly vehicle repairs, insurance premiums and potential liabilities.

It also helps maintain a company's reputation by ensuring fleet compliance with safety regulations and minimizing disruptions to operations caused by vehicle downtime.

"I want my drivers to be safe and I want the general public to feel safe when our drivers are out there."

Nicholas Clemente, Bonded Concrete

How to develop a fleet safety program in 4 steps

Fleet risk management is the top priority for any fleet manager, but enforcing safety policies can be a challenge without the proper system in place. Some fleet managers have difficulty avoiding safety issues, often resulting in accidents and costly expenses. Follow these four steps when implementing and updating fleet safety programs.

1. Define and share clear safety policies

Implementing a fleet safety program begins with setting standards and expectations for your drivers and assets. Start by examining how your drivers use your vehicles and equipment, as well as how you keep track of them. Consider these factors when developing your fleet safety policy:

- Whether drivers take assets home each day or return them to the lot

- What types of tools you have in place for monitoring drivers on the road

- How you keep up with inspection records, licensing and registration renewals

"The more you can get people to buy in on things, in my opinion, the better off you are."

Brent Godwin, Bighorn

If your drivers take vehicles home each day, you may not see them regularly. Having a way to track vehicle status, health and utilization are imperative to ensure your vehicles are operating safely and drivers stay productive.

Once you’ve created a fleet safety policy, distribute this to current employees and include it in onboarding packets for new hires. Regularly communicate the importance of safety to your drivers, and consider incentivizing good driving behaviors.

Hiring trustworthy drivers and regularly communicating the importance of fleet safety keeps your organization safe and helps you avoid accidents and fines.

2. Conduct regular inspections for safety and compliance

Vehicle inspections are a great way for drivers to identify potential safety issues and help prevent future breakdowns or accidents. Whether or not your fleet is legally required to complete daily vehicle inspections, this is a good practice to ensure fleet safety practices are being followed.

Paper inspection forms are tedious, and drivers often breeze through them to get back to their daily tasks. This often results in drivers overlooking critical issues.

Paper inspections are also ineffective for many fleet safety plans because they create gaps in communication. Fleet managers often aren’t informed of issues until they receive inspection forms, which can be days or weeks later.

Pro-tip

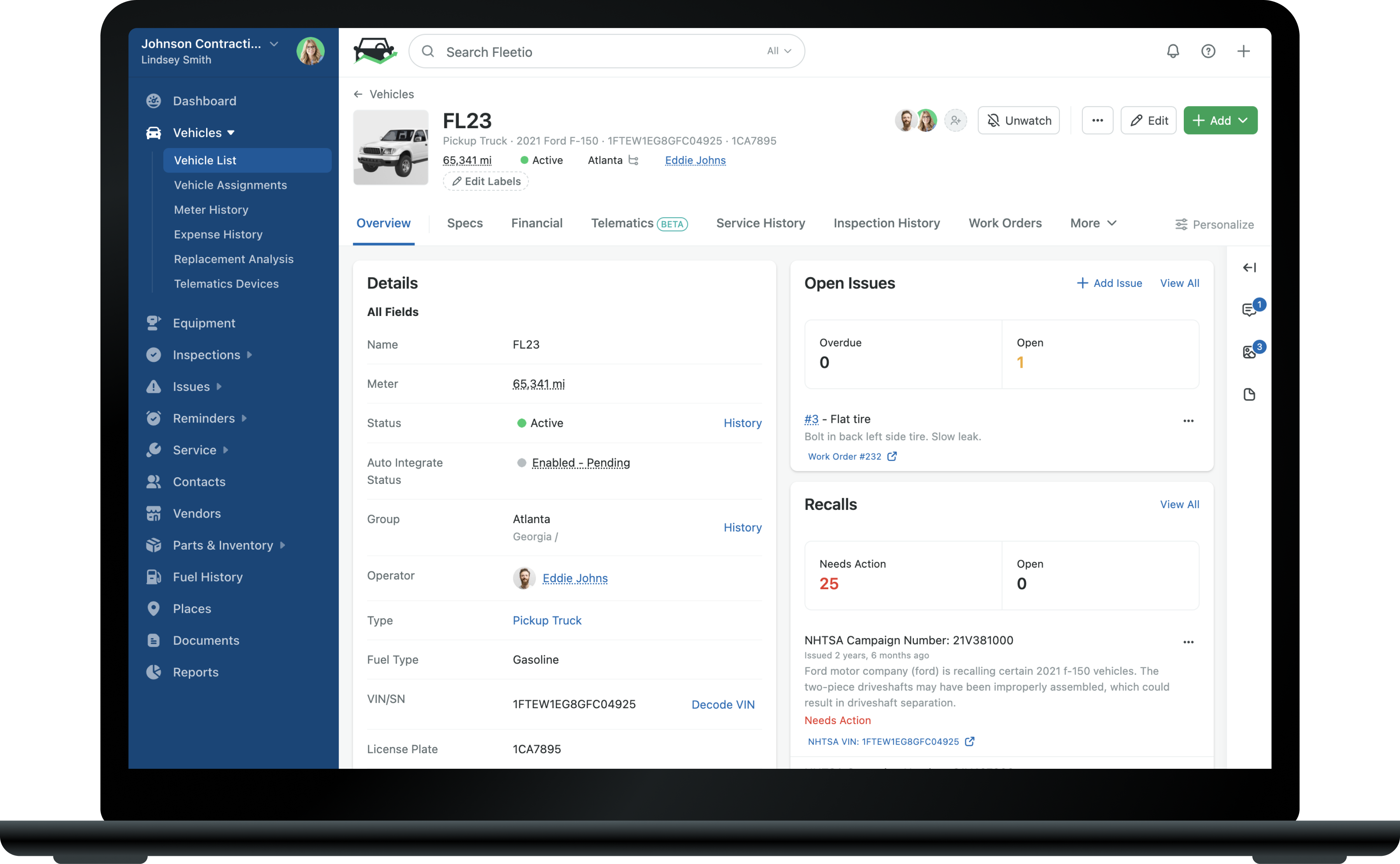

Fleetio's mobile inspection app can surface failed inspection items instantly, giving you near-real-time visibility into potential safety issues in your fleet.

With comprehensive vehicle inspection reports, fleet managers can identify ongoing safety issues that are increasing risks and costing their fleet money. If tire tread is wearing out too quickly on certain vehicles, have a discussion with drivers about harsh braking and speeding. Not only does this mitigate risks, but it also helps you avoid unnecessary expenses that can impact your bottom line.

How inspections improve preventive maintenance

Routine vehicle inspections can also improve your preventive maintenance program. Completing inspections with a mobile app allows your drivers to input odometer readings, which can trigger service reminders, helping you get vehicles into the shop on time for regularly scheduled maintenance.

3. Use assignment history to improve accountability

Scheduling and assigning vehicles is standard practice for any fleet manager, but fleets with outdated management systems often don’t keep a record of vehicle assignments. Looking back at vehicle assignment history is a great way to analyze fleet safety and make better decisions for the future.

Pro-tip

Fleetio allows you to keep a record of vehicle assignments to ensure accountability when it comes to the condition of vehicles.

Leveraging this data allows you to make connections regarding any recurring issues with certain drivers or assets. Perhaps a few of your vehicles need brake repairs more frequently than others, and you see that one driver is connected to those vehicles. You may decide to discuss proper braking techniques with him or her to avoid future issues and improve safe driving habits.

4. Use fleet hardware to enhance driver safety

We'll start by saying that it's not micromanaging to rely on hardware like telematics, GPS and dashcams to ensure the safety of your drivers. All of these are great resources to help protect your team – both from themselves and from others on the road.

While 72% of fleets now use maintenance software, more than half still rely on multiple tools or manual entry. Without integration, safety issues can fall through the cracks – especially in fast-paced operations.

Fleet telematics provide insight into driver behavior. You can set up alerts to unsafe behaviors like speeding and harsh braking to help you stay informed and rectify any issues. This level of visibility helps cultivate trust with your team, encourages safe driving and provides insight into vehicle maintenance.

And dashcams allow you to keep a record of an event in case of an accident. Dashcams are a valuable tool from a liability perspective, but also from a coaching perspective. Modern in-cab cameras are able to use AI to detect unsafe driving practices like cell phone usage and distracted driving.

Evaluate and improve your fleet safety program

Even the most well-documented safety program isn’t a “set it and forget it” process. Regularly evaluating your program ensures it continues to meet the needs of your fleet, adapt to operational changes and improve safety outcomes over time.

Fleet safety self-audit checklist

Ask yourself the following questions to evaluate where your program stands today:

- Do we have a documented fleet safety policy that’s accessible and actively communicated to all drivers?

- Are driver behaviors — such as speeding, harsh braking or distracted driving — being monitored through telematics or hardware?

- Are vehicle inspections completed consistently and reviewed by supervisors or managers?

- Do we track and follow up on safety-related incidents or near-misses with coaching or policy updates?

- Are we meeting our preventive maintenance compliance targets?

- Do we receive real-time alerts about vehicle or driver safety issues?

- When was the last time we updated our safety policies to reflect new risks, regulations or technologies?

If you answered “no” or “not sure” to several of these questions, it may be time to revisit your safety strategy and consider a centralized solution that gives you better visibility into compliance, driver behavior and asset health.

How to measure the success of your fleet safety program

Tracking the impact of your safety initiatives is just as important as implementing them. Here are some key performance indicators (KPIs) to measure over time:

- Reduction in incidents: Fewer accidents, injuries and near-misses signal that your program is working

- Maintenance and inspection compliance rates: Higher completion rates reflect accountability and process adherence

- Driver behavior metrics: Improvements in telematics-based data like speeding, idling and braking patterns

- Insurance trends: A decrease in claims or premiums tied to accident frequency or severity

- Employee retention: A strong safety culture improves satisfaction and retention among drivers and technicians

Pro-tip

Use Fleetio’s reporting features to monitor trends in preventive maintenance compliance, inspection failures and telematics alerts — so you can identify areas of risk and improve safety across your fleet.

Fleet safety management tools: What works and why

The tools you use to manage fleet safety can significantly impact your team’s ability to stay compliant, proactive and connected. Whether you're still relying on paper or spreadsheets, or you've adopted a full fleet management system, it’s important to understand the strengths and limitations of each approach.

Here’s a breakdown of the most common tools fleets use to track safety performance — and how they stack up:

| Tool | Pros | Cons |

|---|---|---|

| Paper forms | Easy to distribute, familiar to drivers, no training required | Prone to loss or damage, delayed reporting, no automation, hard to analyze |

| Spreadsheets | Customizable, low cost, decent for small fleets | Manual entry leads to errors, not scalable, limited visibility, no real-time updates |

| Digital DVIR Forms | Digital inspections with photo proof, real-time issue tracking | Often lacks integration with maintenance or assignment workflows |

| Telematics systems | Tracks speeding, harsh braking, idling and GPS data | Doesn’t capture inspection data or maintenance history, siloed from other systems |

| Fleet management system (FMS) | Centralized platform for inspections, PM, assignments, and driver behavior; real-time alerts and reporting | Requires onboarding, investment, and change management — but offers the most long-term value |

For safety programs to be effective, tools must talk to each other. A centralized fleet management system helps connect the dots between drivers, assets, and policies — so nothing falls through the cracks.

Maintain safety through preventive maintenance

Regular preventive maintenance is a crucial element of any fleet safety program. Routine maintenance tasks like checking brakes, tires, and fluid levels help ensure that vehicles operate at their best, reducing the risk of failures on the road.

Fleetio simplifies the process of managing preventive maintenance, making it easy to schedule and track service tasks across your entire fleet. With automated reminders and maintenance records, Fleetio ensures that no inspection or service is missed, helping fleet managers stay on top of vehicle health and focus on what matters most: keeping drivers and assets safe on the road.

Safe fleets run on smart data

When all your fleet data lives in one place, it’s easier to spot issues, stay compliant and prevent issues before they become potential problems. Bring it all together with Fleetio.

One demo could mean the differenceFleet Safety Program FAQs

What is the purpose of a fleet safety program?

A fleet safety program exists to reduce operational risk, maintain compliance with transportation regulations, and ensure the safety of drivers, assets, and the public. It also supports long-term cost savings by reducing accidents, downtime, and liability.

How often should I revisit my fleet safety program?

Review your fleet safety program at least once a year, or more frequently if your fleet size, asset types, compliance regulations or risk exposure changes. Incorporate incident reviews and performance metrics to guide adjustments.

What tools can improve fleet safety?

The best tools to improve fleet safety include telematics for monitoring driver behavior, mobile inspection apps for reporting issues in real time, preventive maintenance software to reduce breakdowns, and dashcams to document incidents and coach drivers.

How often should vehicle inspections be performed?

Vehicle inspections should be performed daily to catch issues before they lead to breakdowns or accidents. At a minimum, conduct thorough weekly inspections and always inspect assets before long trips or shifts. Frequent inspections are essential for safety and DOT compliance.

Content Marketing Specialist

Laura Flowers is the Content Marketing Specialist at Fleetio. When she’s not blogging, you can find her reading on the couch with her cat or in the studio tap dancing.

LinkedIn

Director of Fleet Content, Fleetio

Zach Searcy is the Senior Content Marketing Manager at Fleetio with more than 5 years of experience in the automotive and fleet industries. His content creation days started in middle school when he and his friends began filming lightsaber battles to upload to a new website: 'YouTube.'

LinkedIn|View articles by Zach SearcyReady to get started?

Join thousands of satisfied customers using Fleetio

Questions? Call us at 1-800-975-5304