Fleet Maintenance Management

Improve uptime and manage entire maintenance lifecycles in one place

Share responsibility across team members and achieve your ideal fleet maintenance workflow. Track and manage every aspect of your fleet’s maintenance from reminders to reporting and ensure nothing slips through the cracks.

automated maintenance alert

Send critical reminders and notifications

to the right people at the right time

Automatically generate preventive maintenance (PM) schedules based on manufacturer recommendations

Improve your vehicle inspection process

Report issues as soon as they appear

Fleets love Fleetio

United Site Services

Kevin Rider

maintenance shop network

Improve efficiency and take back control

of third-party maintenance activities

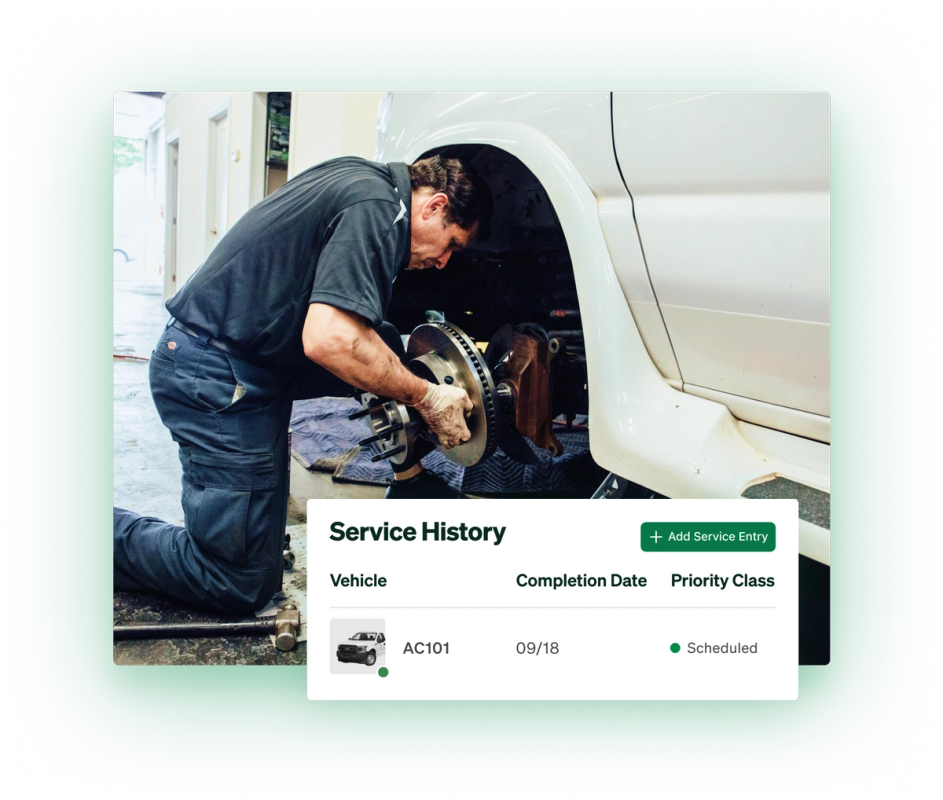

Keep a detailed service history for every vehicle

Avoid phone calls and prevent surprise bills

Get exclusive discounts from our Maintenance Shop Network

Top fleet maintenance features

Preventive Maintenance Scheduling

Fleet Reports & Dashboards

Digital Work Orders

Driver Assignments

Vehicle Inspections

Maintenance History Tracking

in-house maintenance

Effectively track labor, parts and inventory from

issue creation to resolution

Plan, schedule and perform in-house maintenance

Communicate in real time and minimize downtime

Manage parts and inventory and purchase supplies with ease

fleet maintenance reporting

Stop data overload and surface

the right data to stakeholders in real time

Measure the costs and efficiency of maintenance activities

Gain instant insight into spend

Understand the true cost of owning and operating your vehicles

Frequently Asked Questions

Fleet maintenance management is the systematic process of planning, scheduling, performing, tracking and analyzing maintenance activities across your fleet. It includes preventive maintenance scheduling, issue reporting and resolution, work order management, parts inventory control, vendor management and maintenance cost analysis – all designed to maximize asset uptime while minimizing repair costs.

Preventive maintenance scheduling improves operations by: reducing unexpected breakdowns and costly emergency repairs; extending asset lifespan through consistent care; enhancing safety for drivers and the public; improving fuel efficiency; maintaining asset resale value; ensuring regulatory compliance; and optimizing maintenance resources by grouping services efficiently.

Reactive maintenance addresses issues only after a failure occurs, resulting in unplanned downtime, higher repair costs and potential operational disruptions. Preventive maintenance follows scheduled service intervals based on time, mileage or engine hours to identify and resolve potential issues before they cause breakdowns, ultimately reducing costs and improving reliability.

Measure maintenance effectiveness through key metrics including: total maintenance cost per mile/kilometer; asset downtime percentage; percentage of preventive vs. reactive maintenance; mean time between failures; repair order turnaround time; part replacement frequency; warranty recovery rates; and overall fleet availability. A quality fleet maintenance system provides these metrics through customizable reports.

The decision to outsource or perform maintenance in-house depends on several factors including fleet size, asset types, available facilities, staff expertise, geographic distribution and budget considerations. Many organizations use a hybrid approach, handling routine services in-house while outsourcing specialized repairs. A good fleet maintenance system should support both models effectively.

A maintenance management system helps control inventory by: tracking part usage patterns to determine optimal stock levels; alerting when items need reordering; managing parts by location down to bin level; recording part costs and vendor information; tracking part warranties; reducing emergency purchases through better planning; and providing analytics to identify opportunities for inventory optimization and cost reduction.

Digital inspections improve maintenance by: providing real-time issue identification; creating consistent inspection processes; automatically generating work orders from failed inspection items; creating audit trails for compliance; including photo evidence of defects; reducing paperwork and administrative time; improving communication between drivers and maintenance staff; and accelerating the repair process to minimize asset downtime.

More Fleet Maintenance content

Ready to get started?

Join thousands of fleets running on Fleetio

Questions? Call us at 1-800-975-5304